Control loops

I have been getting lots of questions from readers about

control

loops and loop stability, specially relative to switching power

supplies.

And now one of them asked outright that I write a web page about this

matter. Of course, control loops are amply and widely discussed in

electronic engineering books, but most of these books

rely heavily

on math, while most practical, hands-on electronicians seem to abhor

math more strongly than nature abhors vacuum!

So I will try to explain these matters in physical terms most

people

can visualize and understand. I will have to use some

mathematical concepts,

unfortunately, but far less than most textbooks do.

The concept of a control loop

It's all about having some device with an input and an output,

which

has a certain behaviour: Give it some input, and it will produce a

specific output that depends on this input in some way. And then, take

a sample of that output, compare it to what you want that device to do,

and calculate just the exact right input needed to force that device to

produce exactly the output you want. As simple as that.

Not simple enough? Well, look around you! The world is full of

control loops! For example, look at a car moving down the highway. The

car and its dynamic behavior is such a device. The input is the

position of the steering wheel, while the output is the direction the

car actually goes. The transfer function from input to output

is a

complicate one, not linear at all! It may be close to linear while the

car is moving slowly, without any wind. It will turn to whatever side

the steering wheel is turned. But when there is some side wind, the car

will tend to move sideways with the wind, and the steering wheel needs

to be turned slightly just to keep the car going straight! The same

happens when the road isn't perfectly level. When you drive over gravel

roads, the tires tend to slip significantly, and you need more rotation

of the steering wheel to produce a certain change of travel direction.

And as the car goes faster, things get really weird! In a turn at high

speed, the car might follow the steering wheel input up to a certain

amount of rotation, and then suddenly the tires lose grip, and the car

simply stops following steering wheel input! At that point, a totally

different strategy is needed to recover control, like moving the

steering wheel in the opposite direction, until control is re-gained ,

and then moving it more moderately.

With the above, it's clear that to make a car go straight, it

isn't

sufficient to tie the steering wheel in a fixed position. Instead, some

feedback is needed, that closes the loop. This feedback usually these

days is still a human being, sitting behind that steering wheel. It

senses what the car is doing, mainly through its eyes, but an

experienced

driver also feels what the car is doing, through, well, the part of his

body he is sitting on. He processes all the information, and constantly

makes little corrections to the steering wheel position. If this human

feedback system is working properly, the car stays well centered on the

lane, and follows all turns. If the human feedback system is still in

the learning phase, and thus is too slow in processing the

sensed

information, the car will likely go in slalom lines, but still stay on

the road, hopefully. And if the human feedback system is processing the

information far slower than normal, for example because of having

ingested a bottle of vodka, the usual outcome is that the car ends up

off the

road, against a tree, lightpole, or stuck in a building.

This teaches you that control loops need to be fast enough for

the

process they are controlling. Remember this. As a circuit designer,

your task is designing control loops that don't behave like they

have drunk vodka. Or at least not an entire bottle!

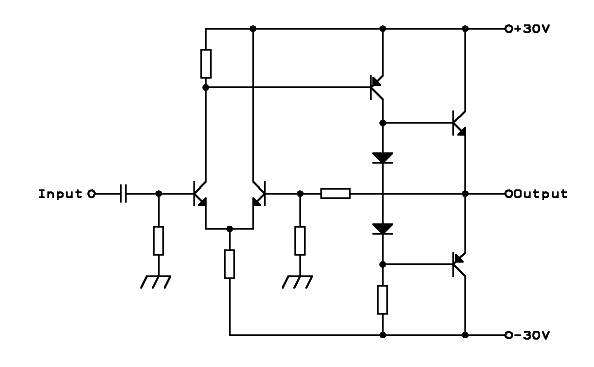

In electronics, control loops are everywhere. Every audio

amplifier

that uses negative feedback has such a control loop.

Regulated

power supplies are important examples, as are the position control

systems for a robot, the autopilot of an aircraft, or the trajectory

control system of a rocket launching a satellite into a precise orbit.

A PLL is basically a beautiful control loop, regardless of whether we

are talking about a simple PLL to decode an FM signal, or a PLL

frequency synthesizer. Industrial process controllers are basically

control loops on steroids, while a humble operational

amplifier is

normally also operated that way.

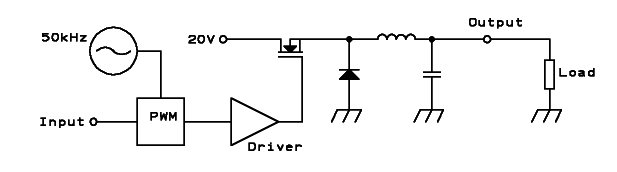

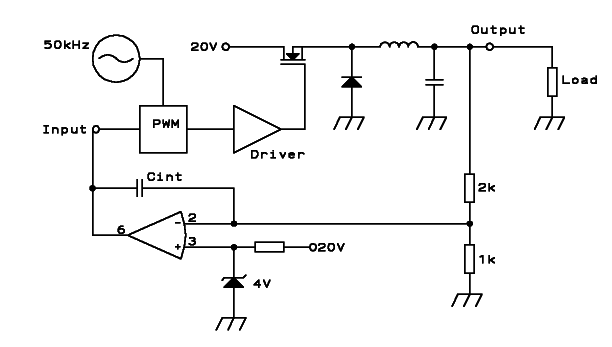

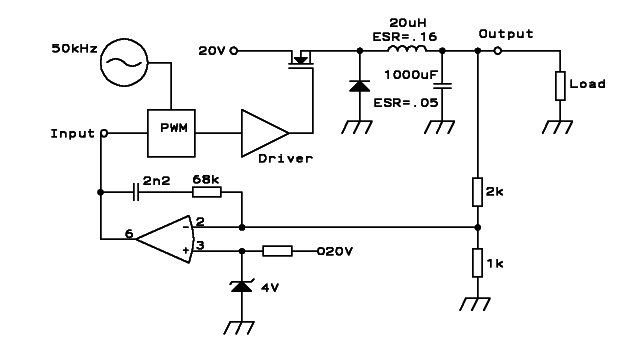

Characterizing the power section

The first thing we need to know, to design a control loop, is exactly

how the device we want to control behaves! And that's very often far

harder than it initially seems. Let's consider the following basic

switching voltage regulator, a simple buck circuit whose duty

is

to keep the ouput voltage constant, at, say, 12V:

We have an oscillator that runs at 50kHz, feeding a Pulse Width

Modulator, which produces a 50kHz square wave output with a duty cycle

proportional to the input voltage. This wave is used to control a power

MOSFET, through a driver circuit. The MOSFET switches on and off,

applying 20V from the primary supply to the ouput filter when it is on,

and leaving that output filter floating when it is off.

Up to this point the behavior is simple. But what the filter does is

not very

simple at all! To simplify it, for a first approach, I will assume that

the load resistance is inside the range that will result

in continuous mode operation. This means that the current in

the

inductor never completely stops, but only fluctuates. Further down I

will add

what happens when this is not the case.

Whenever the MOSFET is off, the inductor

current can only flow through the diode. So, in continuous mode the

voltage at the node of

the MOSFET, inductor and diode will be about -0.7V (one diode drop)

whenever the MOSFET is off, and of course it will be very close to 20V

when the MOSFET is on. This gives us a square wave at this junction,

that has the same duty cycle as the one coming from the PWM, only

at other voltage levels.

If you look at this variable duty cycle square wave on a

spectrum

analyzer, you will see that it has (of course!) strong

contents at

50kHz and its harmonics, but also has a DC component and lower

frequencies. The DC and low frequencies present are an amplified copy

of the signal presented to the PWM's input!

The inductor, capacitor, together with the load resistance,

form a low pass filter. This filter does two things:

- It passes DC and low frequency components, while increasingly

attenuating higher ones. Normally it's designed for a cut-off frequency

much lower than the oscillator frequency, at least in a 1:10

ratio. So it will block the 50kHz signals reasonably well, and

its

harmonics even better, while passing the amplified copy of the PWM's

input signal to the output.

- It will affect the phase of all AC components passing through it.

While the effect on low frequency components is very small, even

negligible, the effect on high frequencies (50kHz, for example) is

dramatic, approaching a complete phase reversal! That means,

simply, that while the MOSFET is switching on, and the voltage at the

input of the filter is going up, the voltage at the filter's output

will be

going down!

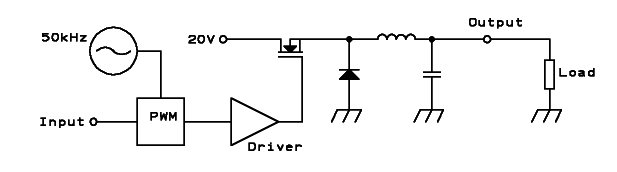

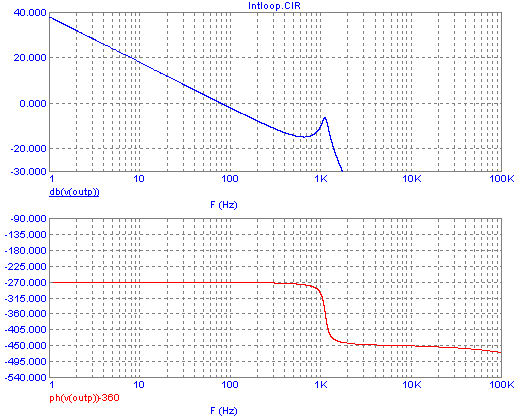

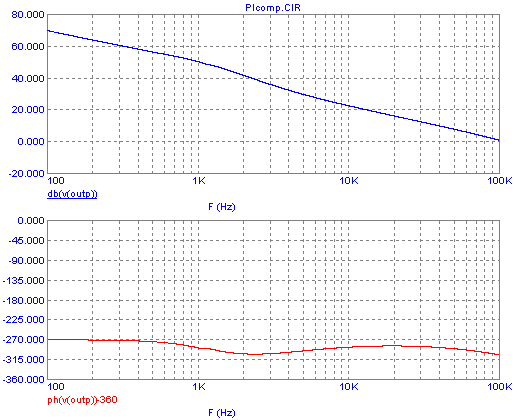

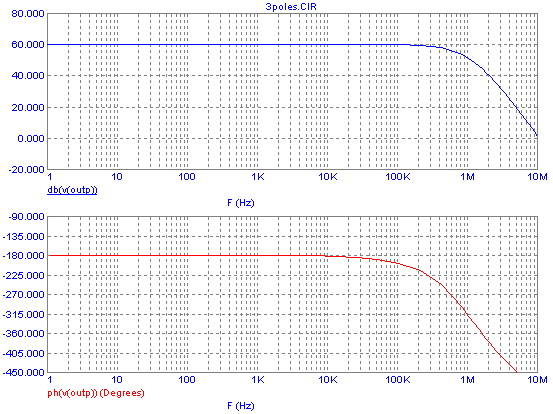

It's a good idea to visualize the behavior of such a filter by means of

a pair of graphs, one showing the gain (or attenuation)

relative to frequency, the other showing the phase shift between input

and output:

Such a pair of graphs is called a Bode plot. To design control

loops, you need to understand Bode plots, think in Bode plots, sweat

Bode plots, even dream of Bode plots!

So, let's start understanding this one. It's about a low pass

filter

having a cutoff frequency slightly above 1kHz, and loaded by resistor

of a moderate value, like an actual power supply might work. I only

cheated a little bit, and simulated perfect components, rather

than the real-world, lossy components we can buy! More about that later.

As you can see, at low frequencies up to a few hundred Hertz

this

filter does essentially nothing: The gain is zero dB, and the phase

shift is essentially zero too, meaning that the output of the filter is

identical to the input. That's entirely logical, considering that the

reactance of the inductor is negligibly small at these frequencies, so

that it essentially short-circuits the output to the input.

But as we approach the resonant frequency, things take a

rather

dramatic turn: The filter starts showing some voltage gain, up to about

17dB in this case, at its exact resonance. In the same frequency range

around resonance, the phase of the output changes dramatically,

reaching 90° phase lag at the exact resonant frequency, and then

approaching 180° lag at only slightly higher frequencies.

At even higher frequencies, well above the filter's resonance, we get a

steady behavior again, with a constant 180° phase lag, and a

negative "gain", or rather an attenuation, that grows at a steady rate

of 40dB per frequency decade.

Why precisely 40dB per decade? This number, that looks like cookbook

material, really comes from a very simple fact: The reactance

of

an inductor rises proportionally to the frequency, while the reactance

of a capacitor falls in inverse proportion to it. So, if we increase

the frequency tenfold, the inductor passes only 1/10th as much current,

and with the capacitor having only 1/10th its previous reactance, it

causes just 1/100th of the original voltage drop. As a result, for ten

times higher frequency, there is a hundred times less output. And a

voltage ratio of 100 times happens to be 40dB.

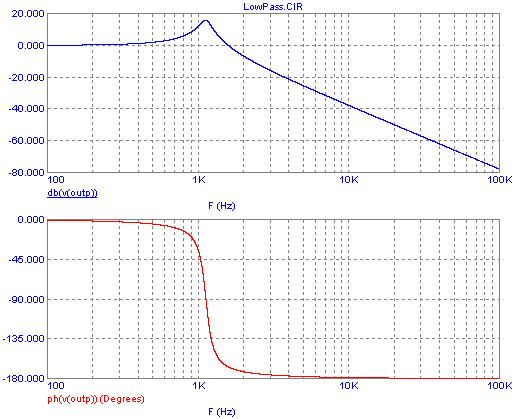

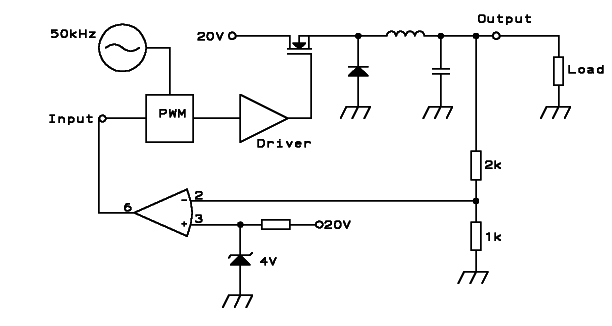

Closing the loop

To turn the open-ended circuit shown above into a

true loop,

you have to take a sample from the output, and process it to obtain a

suitable input signal that you can feed into the input. Designing the

circuit that does this is the

single most feared task many electronic designers have

to face! The evil devil of loop instability, often leading to seemingly

unstoppable self-oscillation, follows these poor fellows into their

sweetest dreams, turning them into churning nightmares!

In a circuit like this voltage regulator, the first thing we need to do

is find out where we are standing, that is, what the present absolute

output voltage is! For this we need a voltage reference, and a

comparator of some sort. The voltage reference can be obtained from a

Zener diode with biasing resistor, but much better accuracy is obtained

from integrated circuits optimized as voltage references. And the

comparator can be implemented with a single transistor, or a pair of

them to cancel out their temperature dependency, but it's far more

common to use an operational amplifier for that task. From a very

simplistic point of view, we could end up with a circuit like

this:

The fundamental operation of this feedback system is simple: The 2k/1k

voltage divider produces a sample of the output voltage, being one

third as large in this case. For a 12V output, this would be 4V.

A Zener

diode is used to provide a 4V reference, and an op amp compares the

reference to the output voltage sample, and hugely amplifies the

difference between them. This amplified error signal is put into the

PWM. And then we hold all thumbs that it will work! The idea is that if

the output voltage gets a little too low, the op amp's output will get

much higher, this will increase the pulse width, thus raising the

output voltage and correcting the error.

But it won't work. At least not very well! Most likely the entire

loop will self-oscillate in a horrible way! Let's see why.

Stability criteria, phase margin, gain margin, and other

buzzwords

Any loop, like the one shown here, has the potential to oscillate, by

taking a signal from the output, putting it into the input, from there

to the output, and on, and on, and on... Whether it will actually

oscillate, or will be stable, can be defined in a very simple way:

- If there is any frequency at which the total loop gain is

exactly unity (0dB), and the total phase shift around the loop is

exactly zero, or 360°, or any multiple of that, the circuit will be

unstable. That means it will oscillate.

- If the above is not the case, but there is any frequency at which the

gain is higher than unity, and the phase shift is like above, then the

circuit will be "conditionally stable". That means, it will not

oscillate while these conditions are maintained. The problem is that

any momentary saturation condition of any part of the loop reduces the

average gain,

so that in practice such a circuit will typically at least momentarily

meet the conditions for instability, and will start oscillating. Once

it starts oscillating, the oscillation by itself keeps driving the

circuit into periodic saturation, self-adjusting the loop gain to that

sweet

value of unity, and thus maintaining the oscillation. So, for practical

purposes, a "conditionally stable" loop is an unstable one.

- If none of the above conditions are met, meaning that at each

frequency either the gain is less than unity, or the phase shift is

not 0°, 360°, nor any multiple of that, or both, the loop will be

stable.

So, to analyze whether our circuit is stable, we need to draw the Bode

plot for the entire loop. This is easier said than done!

We can start anywhere in the loop. Since we already have a Bode plot

for the low pass filter, let's start from there. The next element in

the loop is the resistive divider. It doesn't affect the phase of any

signals, and it divides everything by 3. That means a constant gain of

-9.5dB at any frequency, and zero phase shift. That's a Bode plot so

simple that I won't bother generating it. Combining this Bode plot to

that

of the low pass filter, the result is a new Bode plot for both

sections, that looks just the same as the Bode plot for the filter,

only that it has the entire gain curve shifted 9.5dB down.

The next part of the loop is the op amp. The voltage reference

connected to it only affects the DC response, and since

self-oscillation at DC is impossible, we don't need to bother about the

reference. But the op amp has a very characteristic Bode plot, which we

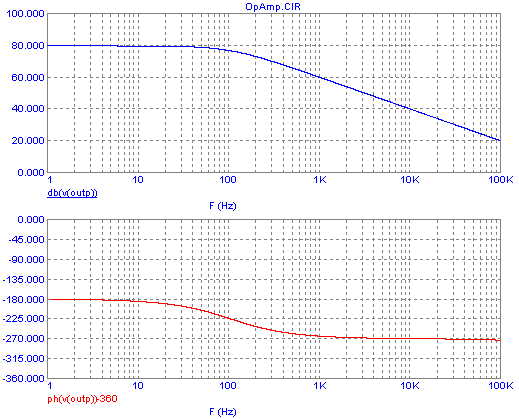

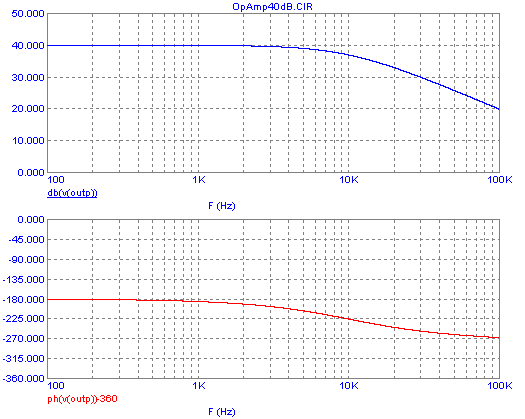

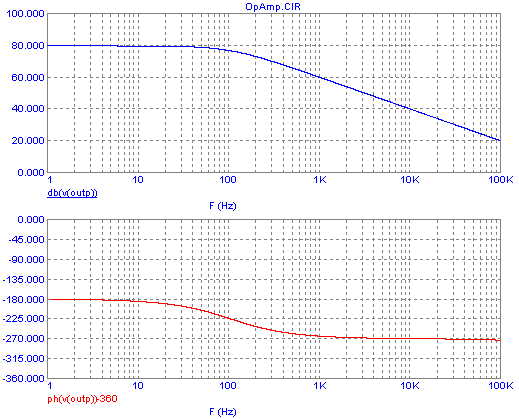

do need to consider. Here is a Bode plot for a typical, modest

performance op amp:

Several things stand out here: Its very high gain at very low

frequencies;

the almost uniform gain drop-off throughout the higher spectrum, at

-20dB per

decade; and its phase shift, which starts from -180° at very low

frequencies, because I'm modeling an inverting amplifier,

and then soon shifts by another 90°, completing that shift roughly by

1kHz! In the gain plot we can see two clearly distinct

frequency ranges of operation:

The very low frequencies up to about 100Hz, where the gain is very

high and constant, and the higher frequency range above 100Hz,

in which the gain

drops at a steady 20dB per decade. Now if we take into account the

phase plot too, we need to consider the op amp as having three distinct

frequency ranges: The low range with constant high gain and constant

-180° phase, up to 10Hz; the high range, with downsloping gain and

constant -270° phase, from 1kHz up; and the transition range, from 10Hz

to 1kHz, in which the gain changes rather briskly from flat to

downsloping, while the phase changes much more gradually from -180° to

-270°.

These curves are typical for any op amp, although the very low

frequency gain, and the transition frequency, depend on the specific op

amp.

Note that when talking about phase shift, 180° is the same as -180°,

90° is the same as -270°, and so on. You should also be warned that

most other authors, when discussing these matters, don't mention the

fact that error amplifiers are usually inverting amplifiers, and so

they would talk about a phase shift changing from 0° to -90° in this

case. It doesn't matter which method you use, as long as you are aware

that in any negative feedback system, like control loops are, there is

always a phase inversion, meaning that the reference of all things is a

-180° phase shift!

In the same breadth I should mention that most authors draw their Bode

plots as straight lines with sharp corners, that approximate the actual

softly curving lines.In my opinion, that's a dangerous practice,

because the actual traces can deviate by several dB and tens of degrees

from the straight

line drawings, misleading a designer into making an unstable circuit!

For this reason I'm using the actual, curvaceous traces in my Bode

plots. They are more beautiful too!

The output of our op amp goes to the PWM. We need to come up with a

Bode plot for the entire cell consisting of this PWM, driver, and

MOSFET. Assuming that we are using the PWM included in typical power

supply control ICs, the input range to the PWM will be typically

something like 1 to 3V, to produce an output from zero to 100% duty

cycle (or close enough to that). The average voltage after the MOSFET

will be this same percentage of the 20V input! So, at 20V input, and

given the total 2V control range, this cell of our regulator has a

voltage gain of 10, which is

20dB.

This holds true from DC to the highest frequencies that still

allow

proper PWM operation, that is, frequencies that are much lower than out

50kHz clock oscillator. When our signal frequency comes into the same

range of the clock frequency, better forget it, because all sorts of

weird things happen!

You might think, at first, that a PWM causes no phase lag. But... it

does! The problem is of a statistical nature: Whenever the input

voltage to the PWM changes, the PWM cannot transfer this change to the

output any faster than the individual pulses happen. So, it causes an

input-to-output delay that averages one half pulse, which would be 10µs

in our example. At low frequencies a delay of 10µs means a negligible

phase delay. For example at 100Hz a cycle takes 10ms, so a delay of

10µs is about one third of one degree phase lag. But at the higher

frequencies the phase lag becomes progressively larger.

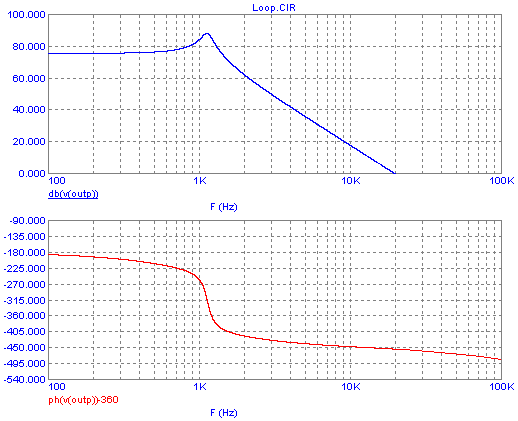

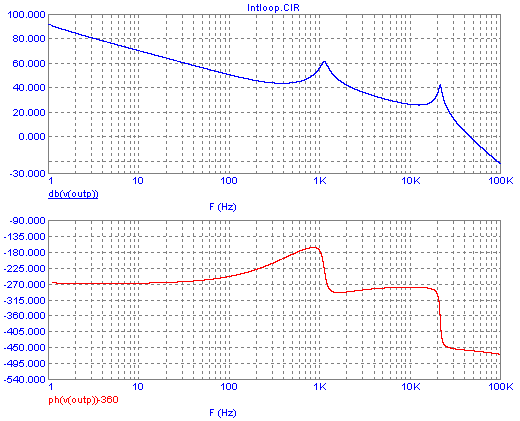

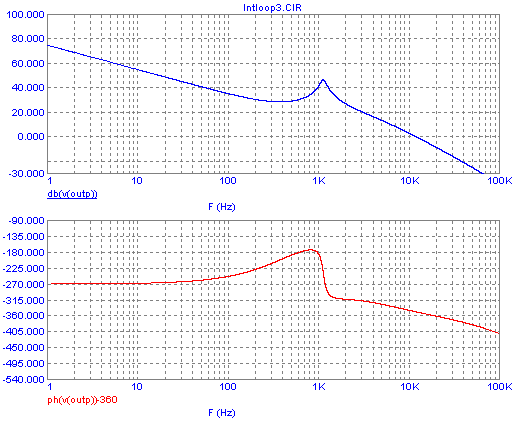

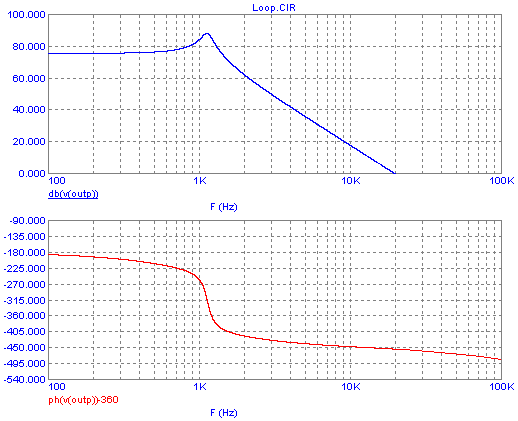

Now we have characterized all elements of the loop, and need to combine

all those Bode plots. The result is something like this:

It's not totally accurate because I was too lazy to model it

in

full, and what's more worrying, because this circuit simulator produces

nonsensical output as soon as the DC gain exceeds 80dB! That forced me

to tweak some things, resulting in a gain curve about 15dB lower than

the real thing, but it's close enough for this crude analysis. The only

facts

you need to

see right now are these: At low frequencies the loop has a very high

gain, which is highly desirable to achieve a precise output voltage,

and the phase shift is close enough to -180° so that we can consider

this to be valid, true, negative feedback. But around 700Hz

the

phase lag quickly grows, and by the resonant frequency of the filter,

around 1.2kHz, it reaches -360°! That means, in addition to the desired

inverting action of the op amp, there is an additional, full 180° phase

lag, coming from the low pass filter, making a total lag of 360°. Now

remember the stability criteria: Where the phase

lag is 0° (or 360°, or a multiple of that), the gain is not allowed to

be 1 or higher. But our circuit has a whopping gain of over 80dB at

this frequency! So it is "conditionally stable" only, which means that

in practice it will be unstable!

The actual behavior of this circuit would be that of a simple

on/off

controlled loop: At first the op amp would drive the PWM to 100% duty

cycle, so that the MOSFET would be continuously on. The output voltage

would rise at a rate determined by the low pass filter, and when it

crosses the 12V barrier, the opamp would ramp down and drive the PWM

into its zero duty cycle range. So the MOSFET would switch off for a

long time, after having done only a few pulses of decreasing width at

50kHz. It would stay off

for a long time, while the inductor keeps delivering current to the

capacitor, and the output voltage keeps rising for a while, until

running out of juice. At that time the voltage starts dropping, and

when it crosses the 12V barrier again, downward, the op amp would ramp

up again, the PWM would again go to 100% duty cycle, and so on.

In short, the circuit would oscillate at the low pass

filter's

resonant frequency,

and the 50kHz oscillator and PWM would be basically defeated! At the

output we would get a 12V average voltage, so the circuit sort of works

- but there would be a large 1.2kHz ripple on it! And the

current

in the coil and transistor would reach dangerous levels. All this would

make

the circuit unusable.

We clearly need to get rid of the excessive gain at the

critical

frequency where the phase lag reaches zero. An obvious thought is to

add gain controlling resistors to the op amp. But this isn't a good

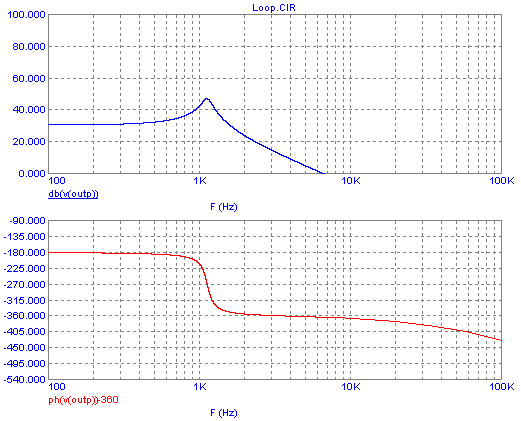

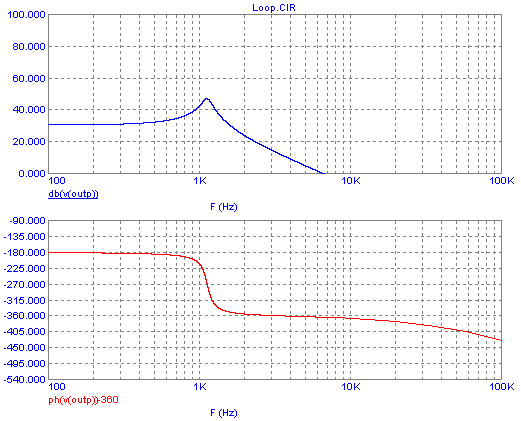

solution! For example, see what happens if we reduce the gain of the op

amp to just 10 (20dB):

What we have now is basically the filter's phase response up to several

kilohertz, because the op amp has a pretty clean 180° phase inversion

up to that frequency, at this low gain setting. The op amp's phase

delay comes in only from 10kHz upwards, bending the phase curve down.

That's good. But we get a total loop gain at low frequencies

that

is only about 30dB. This is given by the 20dB gain of the PWM and power

stage, the zero dB of the low pass filter, the almost 10dB attenuation

of the resistive divider, and the 20dB gain of the op amp. This isn't a

brilliant amount of low frequency gain to have! Any disturbance, for

example 100Hz ripple riding on our 20V primary supply, will get through

to the ouput, with only 30dB attenuation. That's poor performance! And

even worse: At the frequency where the phase lag crosses zero, we still

have several dB of gain, so the circuit would still be

unstable!!!

Of course we could achieve stability by brute force, simply by lowering

the op amp gain enough. But by then we would have very little

regulating action left, rendering the whole circuit pointless!

It's pretty clear what we could use: High gain at low frequencies, but

rolling off fast enough, along with a controlled phase behaviour, so

that we meet the stability criteria while at the same time providing

good regulation!

To do this, we need to know just how low the gain needs to be, at the

phase crossover frequency. This is where the concepts of phase margin

and gain margin come in. Gain margin is simply how much the loop

gain is below unity at the exact frequency where the phase

response

first crosses zero. And phase margin is how many degrees away

from zero (or 360°, or -360°) the

phase is, at the exact frequency where the gain is unity (0dB).

The Bode plot above shows that the gain margin we obtain is about

-13dB, since the gain is about +13dB at the phase zero crossing. And

the phase margin in that plot is roughly -8°. Instead the values that

usually are considered desirable are a phase margin of about 45 to 60°,

and a gain margin of about 6 to 10dB. If a circuit operates under many

different conditions, these criteria should be met at the worst of all

operating conditions.

Clearly we aren't there yet!

Shaping the loop response, poles and zeroes, and the

PID control function

Now it's about high time to learn, if you haven't yet done so, how an

op amp behaves when you connect different stuff to it. Because we need

this tool to shape the response of our error amplifier, to achive good

regulation along with full stability.

You already saw the Bode plot resulting from a naked op amp: Very high

gain at very low frequency, tapering off smoothly at 20dB per decade,

while the phase response starts at the desired value (180° in an

inverting amplifier) at those very low frequencies, and then soon

adds 90° of lag. Now let's see what happens when we add a

simple

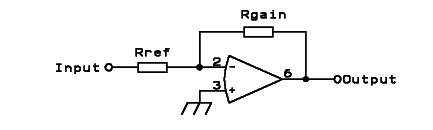

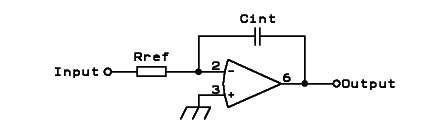

resistive feedback network to the very same op amp, like this,

a

40dB gain inverting amplifier:

We get the following Bode plot:

See how the same op amp that had such a crummy response when left

without any feedback, now has a nice, very stable gain up to several

kHz, and at the same time its phase

delay gets significant only above 3kHz too! This is called a

proportional amplifier, because it amplifies all frequencies by the

same proportion, up to a limit given by the op amp's characteristics.

Above

that range, the op amp internally limits the frequency

response

and causes a phase lag.

Note that what the resistive feedback does, relative to the bare bones

op amp, is simply pushing down the gain in the flat response area,

without changing the position of the sloping gain line. This moves the

intersection of the two lines (or rather, the bend) up in the spectrum,

and with it goes the 90° phase delay.

For a given op amp, the lower the gain you program it for, the wider

will be its flat gain, no-lag bandwidth.

But very often we want an error amplifier to have far more gain at low

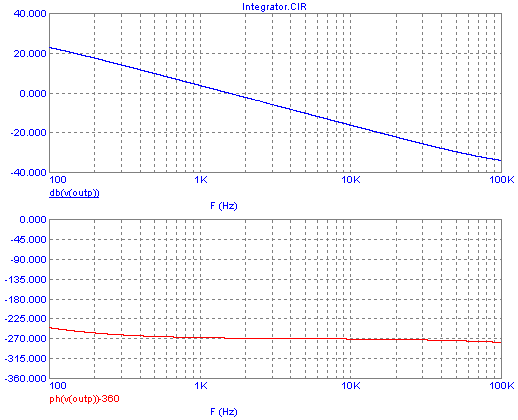

frequencies than at high ones, even within our frequency range of

interest. This is done using capacitive feedback:

This circuit is called an integrator, because its output is the

integral of its input. Put a voltage step in, and you get a ramp out.

Put a square wave in, and you get a triangle wave out. Put

a sine

in, and you get a cosine out - or the other way around, I

don't

remember, being mathematically challenged myself... To non-mathematical

electronicians, anyway, it's the same sine, shifted 90° back in phase.

Its Bode plot is rather boring:

But such boring Bode plots, with very straight lines, are

often the

most useful! You can see that throughout the frequency range in which

it functions as an integrator, it has a gain sloping down at a constant

20dB per decade, and a constant phase shift of -90° relative to the

standard -180° of any inverting amplifier.

The lower limit of this behavior is given by the finite DC

gain of

any op amp, which turns it into a proportional amplifier in the very

low frequency range, tending to very high, constant gain

there,

and only

the normal 180° shift. Just the beginning of this is visible in this

plot, that starts from 100Hz. And the upper limit of the clean

behavior is

given by other internal effects of the op amp, adding an

additional phase delay, but at frequencies far above than our range of

interest.

So, what the capacitive feedback does, relative to the bare-bones op

amp, is basically shifting the sloping part of its gain curve

down, without affecting the flat, low frequency line. This moves the

intersection frequency down, out of the graph in this case. It's easy

to make an integrator, with practical component values, that has an

intersection frequency as low as 0.01Hz!

At DC, the gain of an integrator is always the op amp's open loop gain,

typically 80 to 100dB.

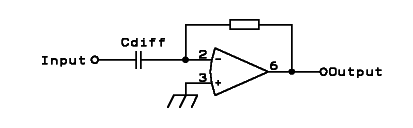

Of course we can also build the opposite circuit, one whose

gain increases with frequency:

This is called a differentiator, because its output is the derivative

of the input: A ramp on the input produces a step on the output, a

triangle at the input gives a square at the output, and a cosine at the

input gives a sine at the output - or the rounder way another, because

I'm still mathematically challenged! Anyway, it shifts sine waves in

the opposite direction as an integrator does.

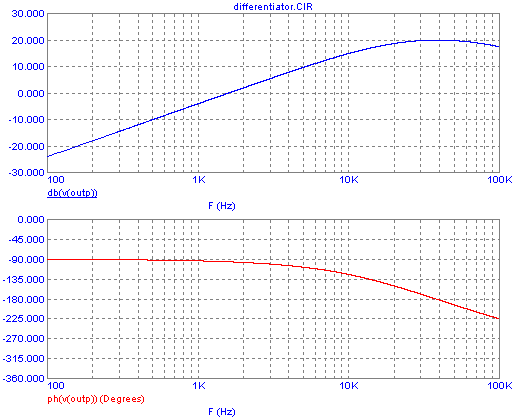

And its Bode plot:

You can see the steadily rising gain, at 20dB per decade, until

reaching a limit given by the op amp's characteristics. The phase shift

is -90°, which is a positive shift of 90° relative to the -180°

of any inverting amplifier. But the imperfections of a practical op

amp, built in intentionally (and necessarily) in the form of a

compensation capacitance, start causing an increasing phase lag from a

few kHz up.

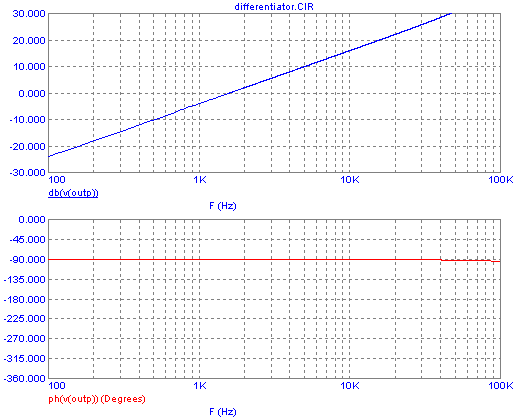

Since this plot looks too crooked, I ran the simulation again, using a

better op amp. The difference is impressive! I kept the same scaling,

to make it obvious:

Here we have a clean differentiator! Keep this in mind: When

you

are caring only about low frequencies, cheap op amps like the 741, 358,

or 324 are fine. But when you need an op amp to perform cleanly at

somewhat higher frequencies, be so good and pay a little more for a

better one! The op amp used for the crooked differentiator is a 741,

and some of the op amps inside power supply control ICs are even worse!

Instead the one used for this last Bode plot is an LF400.

The gain of the differentiator keeps decreasing toward lower

frequencies, so that at DC it reaches infinite attenuation. That means

its output doesn't react at all to any DC voltage at its input.

We can combine the functions of proportional, integrating,

and differentiating amplifiers in a single circuit. For example, this

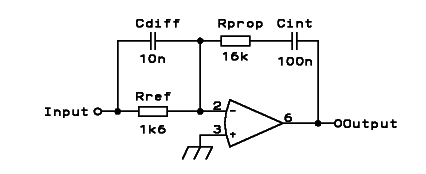

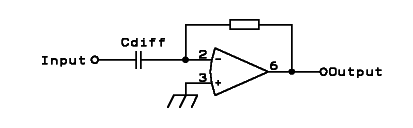

circuit has all three of them:

At DC, both capacitors behave as open circuits, so that the amplifier

has the op amp's full open loop gain. In the low frequency range, the

reactance of the integrator capacitor is high relative to the

proportional gain resistor, so it dominates the series pair. At the

same time, the differentiator capacitance also has a high reactance

compared to the reference resistor, so that in this parallel pair, the

resistor dominates. The result is that in low frequency range the

circuit operates as an integrator.

In the middle frequency range, Cdiff's reactance is still large

compared to Rref, but Cint's reactance has become small compared to

Rprop. As a result, both resistors dominate, and the capacitors are

ineffective. As a result, in this middle frequency range the circuit

operates as a proportional amplifier.

And in the high frequency range - you guessed it - both capacitors'

reactances are small compared to their companion resistors, so that in

the input parallel group the capacitor dominates, and in the feedback

series group the resistor dominates. As a result, the circuit operates

as an differentiator in this high frequency range.

The whole affair is called a PID controller, and you will hear this

buzzword mentioned very often in the context of control theory. PID, of

course, stands for "proportional, integral, derivative". PID

controllers are used very, very often. And I do mean that!

Other authors call it a lag-lead circuit, because it offers

phase lag in some frequency range, and phase lead in another.

To an audio person, this exact same circuit goes under the name of

"bathtub equalizer". Just look at the gain curve below, and you know

why! Lots of bass emphasis, some treble emphasis, with a depressed

midrange. It's a common way to make a cheap ghettoblaster

sound

"like a big rig", at least to the ears of non-discerning listeners. And

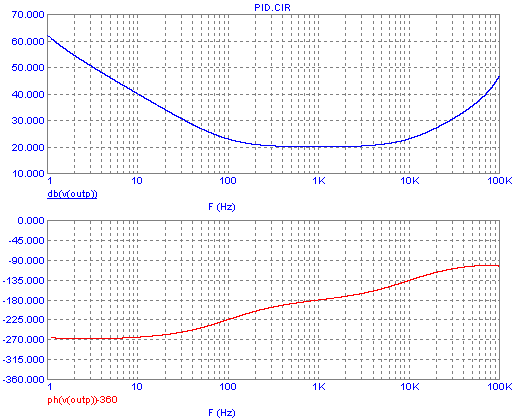

this brings us to its Bode plot:

As you can see, in the low frequency range we have an integrating

behavior, characterized by a -20dB/decade gain slope and a phase of

-270°. In the middle frequency range we have a flat, low gain, the

phase being nominally the -180° of any inverting amplifier. And in the

high frequency range, the differentiator kicks in, with the gain

sloping up at 20dB/decade, and the phase being 90° advanced relative to

the -180° of the inverting amplifier, that is, -90°. This holds true up

to a frequency where the performance of the specific op amp starts to

fall apart.

It's high time now to introduce two more of our friends, poles and

zeroes. A

"pole" is a fancy name given to bending the gain curve down,

for example from flat to -20dB/decade, or from -20 to -40dB/ decade.

Any pole also causes the phase to shift 90° more negative. A "zero" is

an equally fancy name given to the opposite effect, that is, the gain

curve bending up by a step of 20dB/decade, and the phase shifting 90°

more positive.

In the Bode plot above, we can see two zeroes, one located at

100Hz, the other at 10kHz. The circuit actually also has at least two

poles, but they fall outside the frequency range of this plot. One

happens at a very low frequency, where the integrator's gain curve

intercepts the open loop gain of the op amp, probably around 80 or 90dB

gain, and close to one tenth of a Hertz! The other

one, for

this op amp under these conditions, probably happens at a few

hundred kHz. The very beginning of it is visible in the plotted phase

curve.

At the exact frequency of a pole or a zero, the gain is 3dB

off

the "straight line" value obtained by drawing best-fitting straights,

and the phase shift is precisely 45° off the starting value.

This

can be seen very nicely in the plot above.

The design of such a PID amplifier is pretty simple: You first pick a

convenient value for the reference resistor. Then you calculate the

proportional gain resistor to give it the proper mid-frequency gain. If

you want a gain

of ten (20dB), make it ten times as large as the reference resistor.

Then you place the two zeroes. The lower one is placed by calculating

the integrator capacitor value such that its reactance is equal to

Rprop at the desired lower zero frequency, 100Hz in this case. Then you

calculate the differentiator capacitance, such that its reactance is

the same value as the Rref at the desired upper zero frequency, 10kHz

in this case. Finally, if impractical or inconvenient component values

result, you can

scale all four values as you like, increasing the resistances in the

same proportion you decrease the capacitances. Ready!

Phew!

But now we have to put this knowledge to work for us. We still have a

task waiting: Designing a good, fast, stable feedback circuit for our

voltage regulator! We already tried using a simple proportional

amplifier, and found that if we reduce its gain enough to reach

stability, the gain at low frequencies is way too low, resulting in

very poor regulation. So, the next step is trying to use an integrator

instead, which is no more complex than the proportional amplifier. We

only need to replace the feedback resistor by a capacitor, like this:

But this time we will calculate the optimal value! And the logic goes

like this: Since our feedback amplifier is an integrator, it will have

-270° phase shift. So, at the frequency where the lowpass filter of the

power section provides another -90° phase shift, the total phase shift

will reach a full 360°, the condition for oscillation. At this

frequency, which is the filter's resonant frequency of 1.2kHz, we need

the total loop gain to be -6 to -10dB, to have adequate gain margin.

We saw way up in this page that at this frequency the low pass filter

has

17dB gain. The PWM and power stage, fed by 20V, provide 20dB gain. And

the 2k/1k voltage divider provides nearly 10dB of attenuation. So we

have slightly over 27dB of gain left, and we need -6dB or

lower,

which means that at 1.2kHz the error amplifier must provide -34dB of

"gain". 34dB is a voltage ratio of 50, meaning that the integrator

capacitor must have a reactance 50 times lower than the input

resistance to the amplifier, at 1.2kHz.

The effective input resistance, in this circuit, is given by the

parallel equivalent of the 2k and 1k resistors. This is 667Ω. So, the

capacitor needs to have a value of 10µF. If this value seems

impractically high for a nonpolarized capacitor, of course the values

can be scaled, for example you can use 1µF and replace the divider

resistors by 20k and 10k.

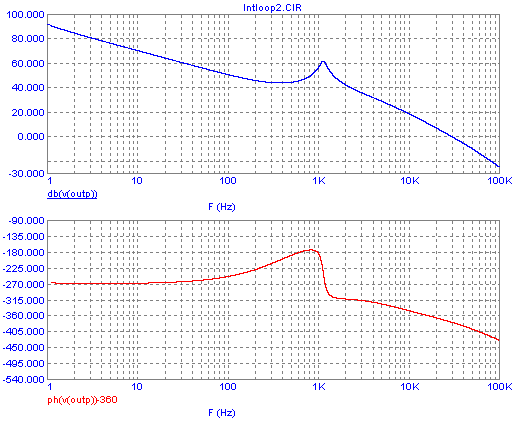

The Bode plot for the total loop, including this integrating error

amplifier, looks like this:

As you can see, at the frequency where the phase lag reaches 360°, the

gain is -7dB, satisfying the gain margin requirement for stability. And

where the gain becomes zero, at about 80Hz, the phase lag is 270°, so

the phase margin is 90°, which is plenty. This means that the loop will

be stable using this integrating error amplifier. But its low frequency

gain is still poor! Quite a lot better than that of a stable solution

based on a low gain proportional error amplifier, but still poor. For

example, if there is 100Hz hum on our 20V primary supply, the low pass

filter doesn't attenuate it at all, as it has 0dB gain there. And the

error amplifier has about -2dB gain at that frequency, and the voltage

divider has almost -10dB, so that the control circuit will do very

little to reduce the 100Hz hum. It will pass right through to the

output, making this a poor regulator!

We need something better. And we need to think a little, what we can do

to make it better. The problem is simple: The low pass filter provides

good attenuation of any unwanted ripple, only well above its resonant

frequency. So, at low and middle frequencies, through and somewhat

beyond the resonant frequency, only the feedback circuit can be used to

reduce any unwanted ripple, noise, and other crap. So, we absolutely

need a sufficiently high gain in the error amplifier, through and

beyond the

resonant frequency of the filter! But the filter introduces a nasty,

quite abrupt 180° phase change around its resonant frequency. This

shift goes from 0° at low frequencies, to -180° at high ones. So, the

best thing we can do, given that we can't eliminate the 180° phase

change, is move it up, so that the total loop phase response, instead

of being -180° to -360°, or worse yet, -270° to -540°, becomes -90° to

-270°! That range accomodates the low pass filter's phase change, and

it also satisfies the phase margin stability criteria, at any frequency!

The tool for achieving this goal is giving the error amplifier a

differentiating action, in the frequency range around the filter

resonance, and up to the frequency where the gain has dropped well

beyond unity. But we can't use a simple differentiator as an error

amplifier, because its response at DC would be none at all! And at low

frequencies it would be dismally low. So, we still need an integrator

to get enough low frequency and DC gain, but then we introduce a zero,

and another zero, both below the filter's resonant frequency. The first

zero compensates for the integrator's phase shift, bringing the error

amplifer's phase back up to -180°. And the second zero brings it

further up to -90 degrees, so that the entire loop phase response would

then start at -270°, move up to -180° and -90°, and then at the

filter's resonance move down again to -270°. Given these

phase shifts,

we can give the error amplifer any gain we want, and still get

stability! The only practical limit to gain is that at very high

frequencies some additional phase lags appear, in the op amp and

elsewhere,

so at those frequencies the gain must be low enough to maintain

stability. But at those high frequencies the low pass filter is highly

effective, so we don't need any error amplifier gain there.

Let's see how to implement this.

Let me start by telling you that the two zeroes might be placed on

different frequencies, or might be placed both on the same

frequency! This actually gives the best low frequency gain,

for a

given very high frequency zero gain crossing. Let's try it, using our

PID circuit. And let's try placing the zeroes on 500Hz, and see what

happens. This should be low enough to have them give a good phase boost

at 1200Hz, and at the same time high enough to avoid reducing the mid

frequency gain too much. Also let's make an integrator that provides a

gain of 40dB at 100Hz, to get reasonable ripple reduction.

Taking our PID circuit, and using our 667Ω equivalent input

resistance for Rref, we neet an integrator capacitor that has

66.7kΩ reactance at 100Hz, to give the 40dB of gain there. This is a

value of 24nF. Then we place one of the zeroes, by means

of Rprop,

which needs to have the same value as Cint's reactance is at 500Hz.

This is 13.3kΩ. And then we place the other zero at the same frequency.

For that we need a Cdiff that has 667Ω reactance at 500Hz.

This

is 477nF.

Here is a little quirk of my chosen voltage regulator circuit: Since I

used the 2k/1k voltage divider as input resistance for the error

amplifier, there isn't an obvious place to put Cdiff! So we place it in

parallel with the 2k resistor, but then it sees three times higher

voltage, so it has to be one third as large! As a result, we need a

159nF capacitor in parallel with the 2k resistor.

Of course in a practical circuit we would use the closest standard

values, such as a 22nF capacitor for Cint, a 13kΩ resistor for Rprop,

and a 160nF or even 150nF or 180nF capacitor for Rdiff.

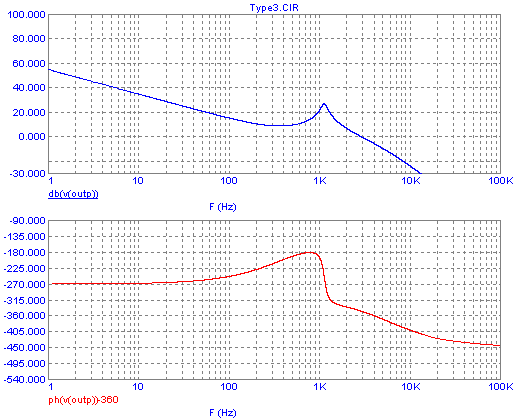

And the Bode plot for the entire loop now is:

As you can see, now the phase for the whole range from DC to over 10kHz

never gets closer than about 65° to the dangerous -360° limit. The

phase shift problem caused by the low pass filter has been removed!

Also the DC and low frequency gain is excellent, at medium frequencies

the gain is still plenty, and life is good - except that a new

resonance showed up at 20kHz! There the phase shift crosses the 360°

line, and the total loop gain there is still high, like 40dB! That

means: Oscillation!

I think that roughly at this time you start realizing that control loop

design isn't for the faint of heart, nor for people seeking instant

gratification!

Actually I'm not sure where this new resonance is coming from. It might

be a quirk of the simulator, rather than a real effect, or maybe it's

real indeed. In any case, it's happening at the frequency where the op

amp reaches its limit, and a downward gain slope begins due to the op

amp proper. Due to the differentiating function, and the relatively

high starting

gain at mid frequencies, at 20kHz the op amp is expected to deliver

close to 100dB gain, which it isn't capable of.

We could do two things: Either build the circuit for real, and try it,

or first roll off the gain at high frequencies, where we don't need

gain, really. The problem is that any gain roll-off at high frequencies

means inserting a pole, which in turn means shifting the phase response

90° down. And that would bring us into oscillation land right away! So

it looks like we need to sacrifice some overall gain.

I will try to do a few things: First, add a pole at 5kHz, by inserting

a 200Ω resistor in series with our 160nF Cdiff. This cancels the

differentiating action from 5kHz up. See what happens:

Much, much nicer! The resonance peak and its associated

sudden

180° phase shift have gone away. But the -360° crossing happens at a

frequency where we still have a positive loop gain. So we still get

oscillation!

At this point, the best course of action seems reducing the overall

gain. Let's try that. We have -360° phase at about 15kHz, where the

gain is around 7dB. If we reduce the gain by, say 15dB, we should get

stability. 15dB is a voltage ratio of 5.6. Let's round it to 6, since

I'm tired at this time of the night, having spent all day writing this

page. So we increase Cint to 144nF and

reduce Rprop to 2.2kΩ. The result:

Success! Now at the -360° phase point, we have -8dB gain, enough to

satisfy the gain margin criterion. But... ouch! The phase

margin

criterion is not satisfied! At 0dB gain, we have very little phase

margin!

Do you like this game? It can be addictive! Maybe after another 10

rounds we solve the problem! ;-)

Math gurus say that they can start from the power circuit parameters,

fill roughly 25 sheets of paper with integral calculus, enormous

intimidating matrixes, a lot of small scribbling along the edges, and

then come forward

with the perfect component values for the error amplifier. The only

problem is that in all instances I have seen them trying to actually do

it, their circuits didn't work as calculated, and had to be tweaked

anyway!

At this point, we could simply solve the problem by reducing the gain

even further. You see, this is like a mantra: If it oscillates, reduce the gain! We

would need to place the -6dB gain point pretty much at

2kHz or so, to just meet the phase margin requirement. But then we are

back to having insufficient low and mid frequency gain! What we need is

either a steeper gain roll-off without the associated phase lag, or

else keeping the phase high enough up to a high frequency, where the

low pass filter cuts the gain enough - but that phase boost would have

to come without any additional high frequency gain! Both are wishful

thinking.

It seems that I cannot come up with a really good, fast, high gain,

reasonably simple, and

unconditionally stable control circuit for this simple voltage

regulator!!! About the best I can do is slightly shift

down the

pole I had placed at 5kHz, and add an additional pole at a somewhat

higher frequency, by means of adding a capacitor in parallel with

Rprop. This is a so-called "Type-III" compensation circuit.

I think I'm right on the money if I assume that by now you are just a

little bit

lost about the exact circuit configuration I'm talking about, so here

is

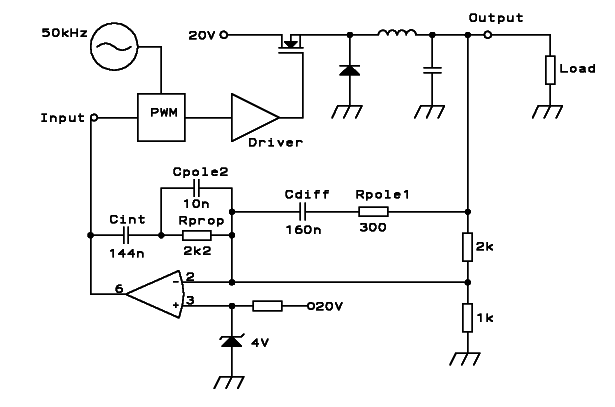

the schematic of the final circuit. It still has the PWM and

driver shown only as blocks, but that shouldn't be a problem.

And this is the full-loop Bode plot it provides:

Looking at it closely, you can see that the gain margin is about the

required minimum 6dB, while the phase margin is a bit tight, barely

20°. So this circuit will have a tendency to ring at about 3kHz, but it

should not self-oscillate. At the same time, its low frequency gain is

high, so the voltage regulation accuracy will be good. In the mid

frequency range, the gain is mediocre to poor, so any ripple on the

primary supply will get through to the output, with a significant

amplitude. Sorry, friends! It's all I can do.

The power of imperfection

Now let me break some bitter news to you: All of our careful tweaking

of this error amplifier was complete nonsense, and utterly useless,

because the power circuit we were trying to control can only exist in

Simulatorland! Because it uses perfect, lossless components. But the

real world just isn't nearly as simple! Real components are imperfect.

Capacitors have some Equivalent Series Resistance, which isn't

negligible in circuits like this. Inductors have a lot of ESR too, and

what's worse, the ESR changes with frequency! At DC it's just the

wire's resistance, but at several kHz and higher an additional

resistance shows up, which is caused by loss in the magnetic core. And

what's even harder to manage is that inductors are quite non-linear

with current! Not only their ESR changes with current, their inductance

also does so, and quite dramatically if you get close to the saturation

zone!

The consequences of this are two: The simple power circuit we were

trying to compensate just doesn't exist in the real world, and what's

worse for the virtual electronician, it's extremely hard to correctly

simulate such a circuit in software! Regardless of how much effort you

invest in getting your simulation right, the real circuit will still

behave differently. You can only get close with the simulation, and how

close you get depends quite a lot on sheer luck, because there are

always some things you don't know about your real circuit. The level of

agreement between

electronic circuit simulators and the actual circuits is about as good

as that of a 5-day weather forecast with the actual weather! To say it

bluntly: Circuit simulators are liars in the same

class as

meteorologists! Both have the best intentions of getting it right - and

both miss the mark by a wide margin!

I tend to use simulators only for relatively simple cases, and when I

know well enough what should happen, to make a reasonable sanity check

of the simulator's output. For this article I'm using Micro-Cap, simply

because it allows me to create nice-looking Bode plots. But when I have

to design an actual control loop, I first measure the behavior of the

actual, real, physical circuit.

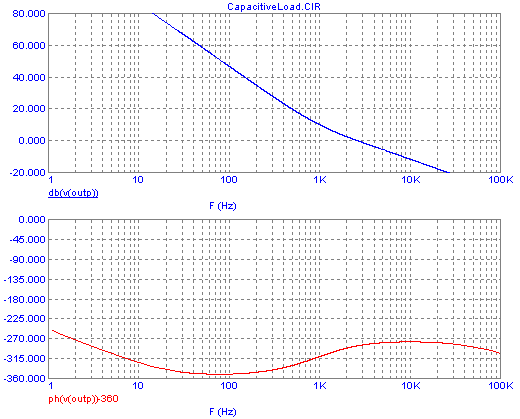

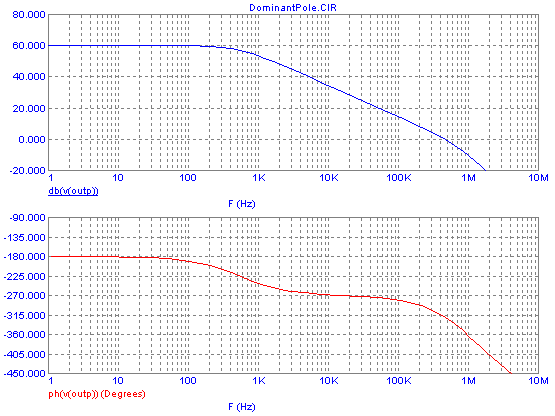

Anyway, for now let's continue using the simulator, but let's simulate

at least some better approximations to the actual behavior of our

circuit! It's very important to do so, because the imperfections of

electronic components are not always a problem. In some specific cases,

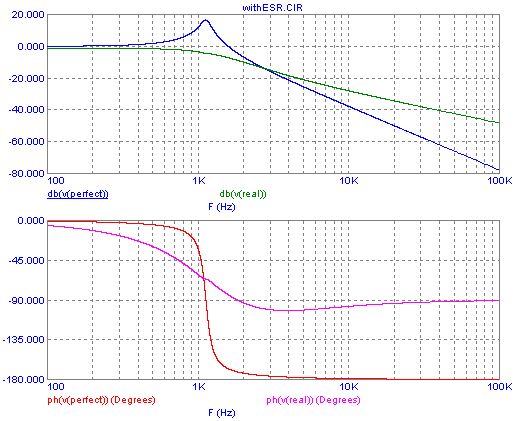

like the one on hand, they can play in our favor! Here is the Bode plot

of our low pass filter, in two versions: The blue gain curve and red

phase curve are the exact same as those in the very first Bode plot on

this long web page, showing the response of an LC low pass

filter

with perfect, lossless components. By the way, the values are 20µH and

1mF (old fashioned people write that as 1000µF), and a 1Ω load. The

green gain curve and pink phase curve are the very same filter, but

adding the ESR for each part. I added 0.05Ω ESR to the capacitor, which

should be quite realistic, and 0.16Ω ESR to the inductor, which implies

an inductor Q factor of 50 at the resonant frequency, which is also

quite realistic for the type of inductors commonly used in switching

power supplies. Now look what happened:

As you can easily see, the resonance peak of the filter has simply

disappeared, and the worst phase lag caused by the real world filter is

only about 100°, compared to the 180° of the theoretical, perfect

filter! And each of these two differences helps us a whole lot in

designing an error amplifier that provides enough mid-frequency gain

along with good

stability!

This subject is important enough to analyze it in more detail, from DC

to high frequencies: At DC and up to about 100Hz, the parasitic

resistances have very little effect. Basically the gain curve is a tad

below 0dB, because the ESR of the inductor forms a voltage divider with

the load resistor. But at all higher frequencies the ESRs are

important. The 20µH inductor has a reactance equal to

its 0.16Ω ESR at 1273Hz, so

that upwards from this frequency the inductance starts to

dominate. As we go below this frequency, the inductor actually tends to

behave ever more as a 0.16Ω resistor! And the 1mF capacitor

has a reactance equal to its 0.05Ω ESR at 3183Hz, so it's mainly

capacitive only well

below this frequency, and instead behaves as a 0.05Ω resistor well

above it! And that explains what happens:

At low frequencies we don't have significant inductance, and instead we

have an RC low pass filter: 0.16Ω in series, and 1mF to ground. The

pole frequency of this combination is 995Hz, and explains the first

half of the phase response bend, and the inflection from constant gain

to a -20dB/decade gain slope. At high frequencies instead the

inductance dominates over its ESR, but the capacitor has become a

resistor, so we have an LR low pass filter in that range! This explains

why that range also has only a -20dB/decade gain slope, and only -90°

phase shift. Only around 3kHz we have a mix of inductance, capacitance,

and both resistances, so there we get slightly more phase lag than 90°,

while the increase in the gain slope is barely noticeable, but present.

At the "resonant" frequency neither the inductor nor the capacitor are

pure enough to cause any noticeable resonance effects!

If the ratios of ESR to inductance and capacitance were slightly

different, putting the inductor's pole frequency right on the

capacitor's zero frequency, we would get a clean

first

order response from this filter, meaning a very smooth -20dB/decade

slope and a precise -90° phase lag, without any overshoot! The inductor

would

basically start filtering at a frequency where the capacitor stops

doing so. The problem in doing this in practice lies in the poorly

defined ESR of capacitors. Manufacturers will guarantee a certain

maximum ESR, but not a minimum, and then the ESR changes a lot during

the life of the equipment, going up as the capacitor ages. So it's

always unsafe to rely on en electrolytic capacitor's ESR to

stabilize a loop,

but it's what almost everyone does in this trade!

What can be done, to remove this uncertainty, is using very low ESR

capacitors, such as plastic film or multilayer ceramic capacitors

instead of electrolytics, and then deliberately adding some series

resistance. Very often this can be done simply by using narrow, long

circuit board traces! Where that introduces too much inductance, a very

low value resistor can be used. And don't shudder thinking of a giant

1000µF ceramic capacitor! Modern high frequency switching systems often

need suprisingly low values of capacitance.

Let's get back to our humble voltage regulator. It's time to cook up a

new error amplifier for it,

now that we have a more realistic Bode plot for the filter's behavior!

The logic will be this: The largest phase lag of the filter is 100°, at

3-5kHz. As long as the error amplifier doesn't introduce much

additional phase lag, the circuit will be stable! But a simple

integrator of course introduces 90° of lag, and that's not acceptable.

So the simplest error amplifier circuit we could try is one having a

single zero, behaving as an integrator at low frequencies, and as a

proportional amplifier at middle and high ones. That would be a PI

controller, or a pole-zero compensator, depending on the lingo you

speak. Pole-zero is because in addition to the zero you introduce

deliberately, there is the natural pole formed by the op amp running

out of open-loop gain at extremely low frequencies.

To have the error amplifier introduce little phase lag at 3kHz, we

need to place the zero well below that frequency. I will try 1kHz. And

then we have just one more decision to make: The overall gain. How much

we can use depends on the high frequency response of the op amp,

because as it runs out of bandwidth it will naturally turn into an

integrator, inserting a pole, causing a -90° phase shift, and at that

point the total loop gain needs to be low enough. Given that I'm using

a pretty good LF400 in my simulation, I will shoot for 40dB

proportional gain. This means:

From very low frequencies to about 1kHz the low pass filter has flat

response, while the error amplifier slopes down by 20dB/decade, from

the op amp's open loop gain to 40dB; while

from 1kHz upwards the low pass filter is the one that slopes down at

that 20dB/decade, while the error amplifier has constant gain! The

result

should be a nice smoothly sloping gain curve, along with an acceptable

phase response.

Given our 667Ω input resistance (from the 2k/1k divider), 40dB

proportional gain needs a 66.7kΩ resistor. Let's use a practical,

available 68K one. And to get a zero frequency of 1kHz, the integrating

capacitor needs to have that 66.7kΩ reactance at 1kHz; that's a 2.38nF

capacitor. Let's use a standard 2.2nF one. Our circuit ends up looking

like this:

And the Bode plot for the entire loop is:

It's pretty nice! The phase margin is around 55°, which is

fine.

The gain margin can't be seen in this plot, as the phase lag

of 360° occurs at a much higher frequency, but the shape of

the

curves seem to show that the gain margin will be ample. The gain at

100Hz (grid ripple frequency!) is 70dB, which will afford a very good

ripple rejection. DC gain is basically the op amp's open loop gain plus

20dB for the power circuit minus 10dB for the voltage divider, which

assures a very precise regulation (as long as our zener is good, that

is...). All is fine, and this circuit should work well. Do you agree?

In fact many switching regulators use simple PI error

amplifiers

like this one. It tends to work well in practice - thanks to filter

component imperfections!

If I needed to deliver a design from which a company would make one

million units, I would invest some further effort, though. For example,

optimizing the inductor's pole frequency and the filter capacitor's

zero, by picking

optimally suited parts, and fine-tuning the error amplifier's zero

frequency, to iron out the phase depression that remains

around 2.5kHz. This circuit can still be improved a lot.

But there are more fundamental issues left to consider, before we

invest any effort in fine-tuning anything. And that brings us to the

next section!

Evil users

Do you know what a user is? Probably not really. It's a contraption,

usually

of human nature, designed and programmed to do all kinds of unexpected,

weird and crazy stuff to the equipment you have so carefully and

lovingly designed! It's well known in the trade that users are not shy

of placing direct, very real short circuits across the outputs of power

supplies, and that's why every designer who knows users will include a

good, effective short circuit protection scheme in each of his designs.

But that just barely scratches the surface! Users will think nothing

bad about running a power supply without any load at all, or with a

very light load. Why should they suspect this is a problem? Rarely will

users load a power supply with a nice, well defined resistor, as I have

done throughout this saga. Instead they might use the power supply to

power some electronic equipment, that has an internal linear regulator,

and such equipment draws a constant current. That means, it has

infinite input resistance! For stability effects, that's just as bad as

running a power supply without any load - but with unknown, possibly

intense and variable current being drawn! Even worse, many evil users

will use a power supply to power some equipment that has yet another

switching regulator in it. And switching regulators are nasty things -

you should know that by now - and one of their nastiest characteristics

is that they exhibit negative resistance at their input! The more

voltage you give them, the less

current they draw. Now if running a regulator like ours into an

infinite load resistance is a problem, just imagine what will happen to

stability if you run it into a negative load resistance! You can make

an LC filter oscillate by connecting a negative resistance to it,

without needing a control loop at all!

Some users are more evil than evil! They will connect electronic

equipment to your power supply, that has a big, good electrolytic

capacitor at its input. This capacitor ends up in parallel with the

capacitor of your low pass filter, and that's the bitter end to all the

intense work you have put into optimizing the loop response!

Because

adding that external capacitance pushes down the resonant frequency of

your low pass filter, totally changes its characteristics, and only

Tesla knows what will happen to your loop!

Do you know who the superlative exponents of evil are, in this regard?

Golden-eared audio fans! Of course, I have to say in their defence that

most of them wouldn't ever use a switching power supply to power any of

their ultra delicate, oxygen-free-copper-cabled, 0.00000000001%

distortion

audio equipment. But if one of them should try to do it, he will

certainly "improve" your power supply by planting a big, 10 Farad (at

least) supercapacitor across its output, to provide the "reservoir"

capacitance he believes his power amplifier needs for those crunching

bass notes.

Now imagine what that does do your low pass filter's characteristics!!!

And still these audio fans are not the absolutely most evil users on

earth. Can you imagine who is even worse? Probably not - but I have

witnessed them: Car owners! And do you know why? Well, watch any car

owner who needs to drive from here to there now,

proudly jumps into his shining car, turns the key - and nothing much

happens,

due to a flat battery! Such a car owner is instantly turned

into

a Mighty Monster, desperately looking for anything that will provide

his beloved car the dearly needed 12 volts at umpteen amperes, to get

it running. If another car with a good battery and a set

of jumper wires are nearby, you are safe, so relax... But if

your 12V power supply is the suitable object nearest to this

enraged

specimen of the wheeled race, resignation is the only thing I can

recommend - because your power supply will

be connected directly to that battery! And if the golden-eared audio

fan's 10 farad capacitor was bad enough, well, the average car

battery

behaves roughly like a 200,000 farad capacitor, with a 0.002Ω ESR! That

for sure pushes your filter's resonant frequency into

the millihertz range, and your gain margin becomes about

-100dB!

So, it looks like we need to consider the effects of load impedance on

our circuits.

It turns out that the regulator we are analyzing is pretty

tolerant of widely varying load resistances, at least from the point of

view of filter characteristics. We will see other problems later. But

load capacitance definitely causes trouble. For example, this is what

happens with a moderately large electrolytic capacitor (0.1F, 0.001Ω

ESR)

connected to the output:

There isn't any trouble in the high frequency range, of course - with

such a big filter cap there just can't be any significant high

frequency signal, right? But around 100Hz we have a terrible phase lag.

As it is in this plot, the regulator will ring severely on any 100Hz

signal - and that means that the grid ripple output with that

big

capacitor will be worse than without it!

Our audio fan wanted to do

good by slapping the big capacitor on the power supply, and what he got

instead is bad hum!

Don't forget that my simulation is very basic. In a real circuit, there

are several elements providing some additional phase delay. It's likely

that in this case those additional delays would be enough to reach 360°

phase lag, and then the power supply would break into self-oscillation

at roughly 100Hz, as soon as this big capacitor is connected

to it!

To make a power supply more tolerant of such abuse, we need to bring

its phase response closer to the optimal -180°. Ours is at or below

-270° over the entire spectrum, and that's workable under normal

conditions, but not very tolerant of difficult loads.

When a really difficult load is connected, such as a battery,

everything depends on the ratio of "capacitance" to series resistance.

A very good, new car battery that has a very low ESR can throw

the

loop totally out of stability, while the same battery after 2 years of

use will have developed a much larger ESR, and will appear mostly like

a

resistive load to the power supply, causing no problem! A

practical hint for evil car owners who see themselves unsurmountably

tempted to

connect a power supply to their batteries: Use a longish, not very

thick wire. That might add enough series resistance to keep the loop

stable!

Discontinuous mode

If you are gifted with a very good memory, you may still remember that

very near the beginning of this article I told you that I would base

the analysis on the regulator running in continuous mode; and that I

explained briefly what continuous mode is. Well, a practical switching

regulator will typically run in continuous mode only above a certain

minimal load current. Below this limit, the inductor current will be

discontinuous, and that opens a whole new can of worms!

In continuous mode the average voltage after the power transistor is

basically an amplified copy of the PWM's input voltage, the

amplification factor being defined by the primary supply voltage

divided by the PWM's input voltage range.

But this is no longer true as soon as the load becomes small enough for

the regulator to operate in discontinuous mode. Instead, the output

voltage will then be the integral of the duty cycle: Its value will

depend

not only on the duty cycle, but also on how long it has been working at

this duty cycle! At zero load, if given enough time the output voltage

will climb to the full 20V input, regardless of how narrow the pulses

are! The only way to stop the voltage from climbing under no-load

condition is to reduce the pulse width to zero, that is, disable the

pulses

altogether.

In terms of gain and phase this means that at reduced load the

power stage's gain increases, and at zero load it has infinite DC gain

and

a 90° phase lag! This is bad news, as it makes almost any such

switching regulator unstable at zero load. That's the reason why many

manufacturers state a minimum load requirement for their switching

power supplies, and prohibit operation at a lower or zero load.

But this issue isn't really as bad as it sounds. And that's because the

problem is self-limiting, in a way: If the loop tries to start a

self-oscillation, it will try to alternately pull the output voltage

up, and then push it down. Well, when it's trying to pull it up, the

charging low pass filter capacitor takes a current and thus acts as a

sort of load, thus

reducing the power circuit's gain and phase lag and removing

the reason for the

instability. And when that stops, and the control circuit tries to pull

the voltage down - it can't! All it can do is setting the pulse width

to zero, thus preventing any pulses, and this effectively opens the

loop, pushing the loop gain down to zero!

So, instability does occur in discontinuous mode operation, but it

usually doesn't have any really terrible consequences. If such a power

supply

is running at an extremely low load, you would expect the power

transistor to conduct a continuous train of extremely narrow pulses.

Instead it will conduct short series of brief pulses, interspersed with

longish times of no pulses at all. Technically the control loop is

self-oscillating, but in practice this causes no major problem. The

output voltage will stay constant enough, because during those pulse

groups the current delivered to the filter capacitor is still rather

small, so it only charges by a small amount, and during the no-pulse

times the voltage drops very slowly too, due to the low load.

And that's why most designers don't lose much sleep over the problems

of discontinuous mode operation! And yet it's better to avoid this

instability, even if it's only for noise reasons: When the control

loop is unstable, and the power stage runs in bursts of pulses, there

are relatively strong audio frequency components in the current flowing

through the inductor, and any transformer the circuit may have. In some

cases this creates audible noise due to magnetostriction of the ferrite

cores. A rough,

irregular hissing sound is typical. If you ever hear a switching power

supply emit that kind of noise, you

know that its designer didn't do a clean job!

Current-mode PWM

To allow better, faster, simpler control loops, it's sometimes a good

idea to use current-mode control, instead of what's commonly but

slightly misleadingly called voltage-mode control. Voltage-mode control

is what our regulator above uses: Each pulse is started on time, at

regular intervals, by a clock oscillator, and ended after another

specific time determined directly by the error amplifier's output. In

current-mode control each pulse is started exactly in the same way as

in voltage-mode, but the pulse width isn't directly controlled by the

error amplifier. Instead, the error amplifier's output is compared to a

sample of the instant inductor current, and each pulse is ended when

the inductor current has reached the value dictated by the error

amplifier. So, the error amplifier directly controls the peak current

in the inductor, and the pulse width ends up being whatever it needs to

be to achieve that current.

This difference has several implications. One is that the amount of

current pumped into the output circuitry no longer depends on the

primary supply voltage. That means, a current-mode controller

automatically compensates for changes in the primary supply voltage,

such as 100Hz ripple, without the control loop needing to care about

it! This is called "feedforward". But an even larger advantage is that

since the error amplifier is

now directly controlling the inductor current, and thus the current

delivered to the filter capacitor and the load, the phase lag caused by

the

inductor is completely removed from our loop calculations! We no longer

need to

care about it! That means that our LC filter now can never have more

than 90° phase lag, and that both in the very low and in the very high

frequency range it has zero lag!

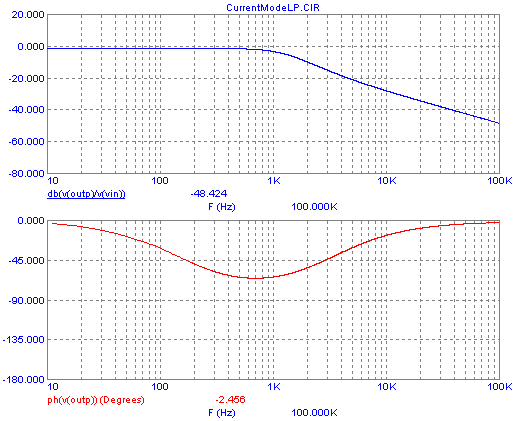

This is how the Bode plot for our LC lowpass filter, complete with ESR,

looks when the filter is driven in current-mode:

Note that the gain curve is the exact same as in voltage-mode control,

but the phase lag doesn't ever reach even close to 90°, and

returns to zero at high frequencies. The explanation for the phase

curve: At low frequency, the capacitor is an open circuit, and we are

just pumping controlled current into the load resistor. So, zero phase

shift. At around 20Hz the capacitor starts becoming significant in

parallel with the load resistor, thus causing some phase lag. But from

1kHz up, its ESR starts becoming significant, pushing the phase back up

by making resistances dominate! The inductor, which caused

a 90°

lag in the high frequency range in voltage mode, cannot do so now,

since we are controlling its current rather than a voltage applied to

it. But the inductor stays fully effective in filtering the 50kHz

switching frequency, keeping the transistor current from

spiking,

and storing energy.

Designing an error amplifier for a current-mode regulator is trivially

simple. A PI circuit with its zero placed at a somewhat lower frequency

than that of greatest phase lag works very well and is quite

uncritical. In

some cases a plain simple integrator works well enough, and that's

often seen in power supplies using simple control-mode ICs such as the

UC3842. I have also successfully used simple high gain proportional

amplifiers, which eliminates the low frequency phase lag of an

integrator, and thus avoids the problem of low frequency instability

when a battery is connected to the output, shifting the filter's

frequency way down. With a proportional amplifier, it's good practice

to add a small feedback capacitor to limit high frequency gain, to

reduce jitter. That means, place a small capacitor in parallel with the

feedback resistor, calculated to give a pole at maybe one tenth the

switching frequency. The resulting phase lag at high frequencies is

almost always well within the healthy range.

The gain of the power section in a current-mode regulator depends on

the load resistance. The higher the load resistance is, the higher is

the gain. As the load resistance goes up, also the pole formed by it

with the filter capacitor goes down in frequency. At no load, this pole

can sit in the millihertz range, causing the -90° shift region of the

low pass filter to extend into that very low frequency range. And the

gain tends to be extreme. For this reason, an integrating

error

amplifier, which adds another 90° of phase lag, can easily make the

loop unstable, and so it's undesirable in ciurcuits whose loads may

become very light. Instead a proportional error

amplifier works fine, because at no frequency the low pass filter adds

more than 90°lag, so that with the lag-free proportional amplifier we

can use essentially any gain we want, without risking instability! In

the high frequency range, our proportional error amplifier will

naturally degrade into an integrator, and cause 90° phase lag. Its pole

frequency will depend on the characteristics of the op amp used, and

the gain we have programmed: Lower gain, higher pole frequency. As long

as the pole frequency is high enough for the error amplifier's phase

lag to fall into the range where the low pass filter capacitor's ESR

has pushed the filter's phase lag back near zero, there will be no risk

of oscillation.

To avoid excessive pulse width jitter, it's a good idea to avoid

unnecessarily high error amplifier gain at the circuit's switching

frequency. Depending on the op amp we use, and the proportional gain we

program it for, we might need to deliberately reduce its pole

frequency. This is done by adding a small feedback capacitor, in

parallel with the feedback resistor. The pole frequency of course will

the one at which the chosen capacitance has a reactance equal to the

feedback resistor's value.

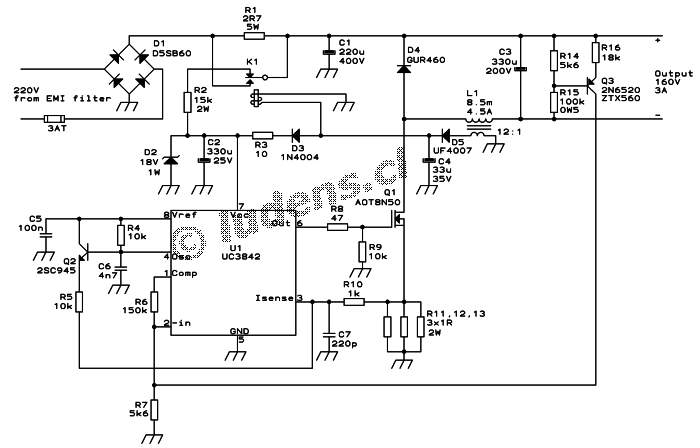

As a practical, working example of a current-mode voltage

regulator with

a simple proportional error amplifier, you might want to have a closer

look at my 160V,

3A motor power supply.

It uses the ubiquitous UC3842, and the error amplifier is a simple

proportional one, with a 150kΩ feedback resistor and a 5.6kΩ input

resistor, giving it 30dB gain. Let me use this circuit to illustrate

some of the computations in a current-mode regulator:

As you can see in the UC3842's datasheet, a 3V change at the output of

the error amplifier will make the peak current vary from zero to its

maximum possible value. This maximum value is set by a 1V internal

limit, and internal 1:3 divider, and the external sensing resistance. I

used 0.33Ω, so that

the maximum current possible is 3A. This means that the pulse width

modulator of this current-mode IC, in my configuration, will have a

transconductance of one ampere per volt, very easy to remember.

You need to be aware that the current we are controlling here is the