Improved single-cell LED flashlight

Being a

flashlight builder since age 7, I can't resist the temptation to build

more and more of them, even 50 years later. The technology has changed,

but the fun remains the same.  Flashlights

can be large and powerful, or small and convenient to carry. In

the latter category, flashlights using a single cell are very

convenient, due to their size and usage simplicity. In the old times of

incandescent bulbs, all it took was a 1.2V bulb, placing it in a

reflector and wiring it up with a battery, so that flashlight building

was a purely mechanical task. But in 2015 the device of choice is the

LED, due to its far better efficiency and reliability. And since white

LEDs need around 3V to operate, they require electronics to be used

with a single, cheap AA cell.

Flashlights

can be large and powerful, or small and convenient to carry. In

the latter category, flashlights using a single cell are very

convenient, due to their size and usage simplicity. In the old times of

incandescent bulbs, all it took was a 1.2V bulb, placing it in a

reflector and wiring it up with a battery, so that flashlight building

was a purely mechanical task. But in 2015 the device of choice is the

LED, due to its far better efficiency and reliability. And since white

LEDs need around 3V to operate, they require electronics to be used

with a single, cheap AA cell.

I had already built single-cell LED flashlights

before, using several small LEDs in series, but when I stumbled across

half-watt LEDs with built-in lens, it struck me that these are ideally

suited for homebuilt flashlights using a single AA cell. So I set out

to build another nice little lamp.

This one has SMD electronics,

on a tiny printed circuit board, and a machined aluminium body. Instead

of a switch, the rear end is screwed slightly out to turn the lamp off,

by opening the battery contact.

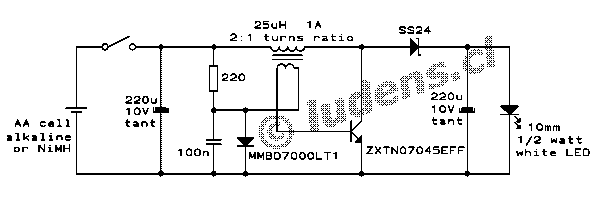

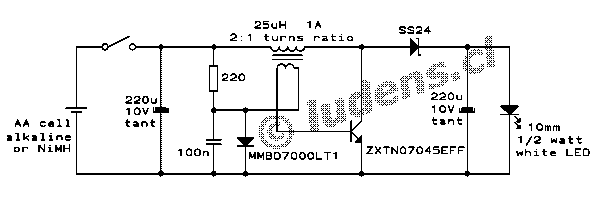

The

circuit is about as simple as it can be: A free-running, self-excited

boost converter, using a low saturation voltage transistor and a

Schottky rectifier, to converter the input voltage to what the LED

needs. This circuit is able to work down to a very low input

voltage, making full use of the battery cell.

The

circuit is about as simple as it can be: A free-running, self-excited

boost converter, using a low saturation voltage transistor and a

Schottky rectifier, to converter the input voltage to what the LED

needs. This circuit is able to work down to a very low input

voltage, making full use of the battery cell.

I used a

factory-made SMD inductor, removed from a junked portable CD player,

along with a few new SMD parts. The inductor got a hand-wound secondary

winding, for the feedback. I adjusted the operating power by

selecting the proper value for the resistor in the circuit, which

controls the transistor's base current, thus defining at what collector

current it will desaturate and thus end the inductor charging in each

cycle.

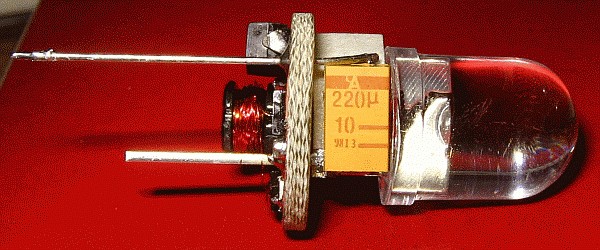

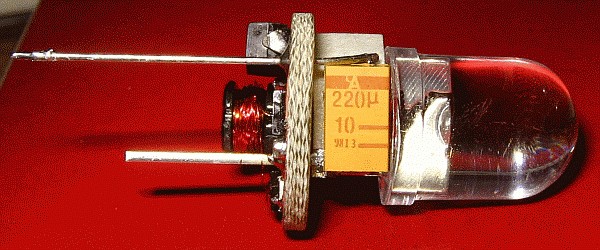

A little round single-sided printed circuit board was made,

which carried all the components, assembled in a very compact way. The

LED, which is a 10mm through-hole type, goes on the non-copper

side, along with the two tantalum capacitors, which make good use of

the space between the board and the LED. All other parts are installed

in normal SMD style on the copper side of the board.

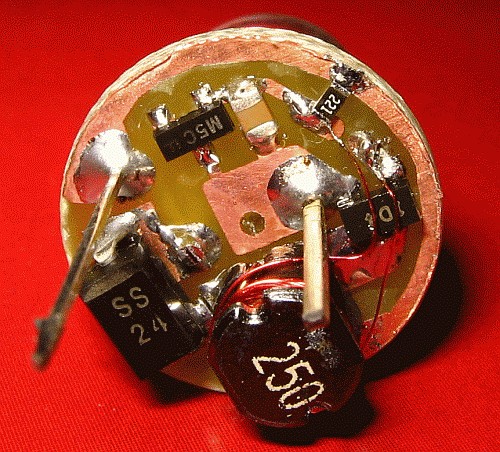

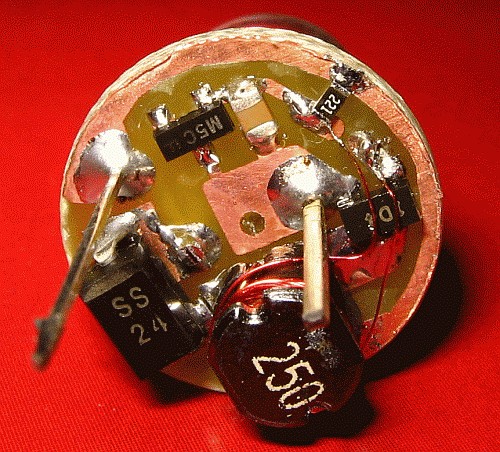

A little round single-sided printed circuit board was made,

which carried all the components, assembled in a very compact way. The

LED, which is a 10mm through-hole type, goes on the non-copper

side, along with the two tantalum capacitors, which make good use of

the space between the board and the LED. All other parts are installed

in normal SMD style on the copper side of the board.

As you can see, even this small board has a lot of space left, since the circuit is so simple.

As you can see, even this small board has a lot of space left, since the circuit is so simple.

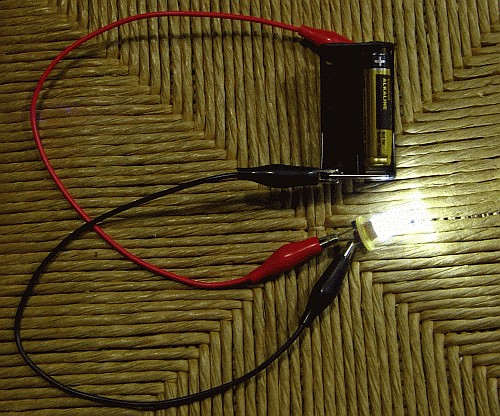

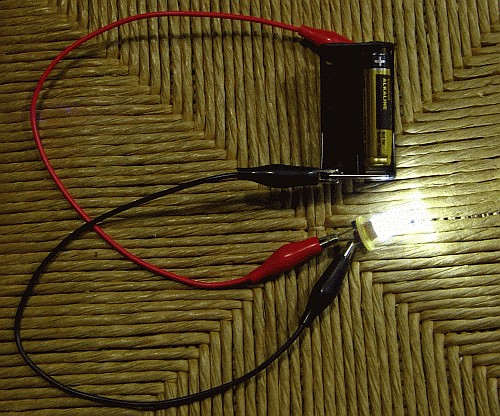

For

the tests I left one LED pin and another piece of wire stick out, to

make convenient connection points for the battery. Later, not shown in

this photo, I clipped the right-side wire and soldered a small brass

cylinder into/onto the center hole, to act as contact point for the

negative battery pole. The wire on the left side, which is the positive

connection, was simply bent to act as a spring and make contact to the

aluminium housing, whose cap connects to the battery's positive side.

That's very crude, but sort of works. Feel free to use a better

arrangement, that doesn't use aluminium as contact material...

This

shows how small the assembly is. Well, it's a 10mm LED, and the PCB was

made 15mm diameter, the same size to which I turned the inside of the

housing, to fit the AA battery, which may be up to 14.5mm in diameter.

This

shows how small the assembly is. Well, it's a 10mm LED, and the PCB was

made 15mm diameter, the same size to which I turned the inside of the

housing, to fit the AA battery, which may be up to 14.5mm in diameter.

Playing with the little lamp, before building the housing.

Playing with the little lamp, before building the housing.

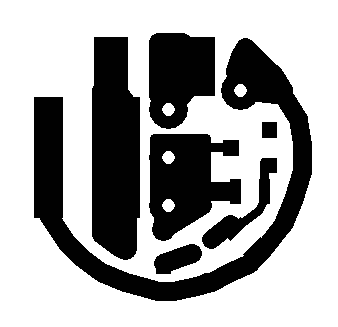

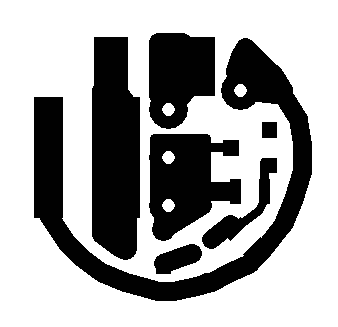

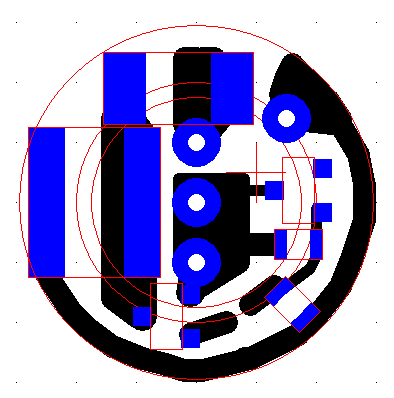

Here is the PCB layout. You have to scale it so that the outer diameter of the outer copper arc is 15mm.

Here is the PCB layout. You have to scale it so that the outer diameter of the outer copper arc is 15mm.

It's

seen right onto the copper, with no mirroring, so make sure to invert

it (mirror view) if you want to print the image and place it ink-down

onto your sensitized board.

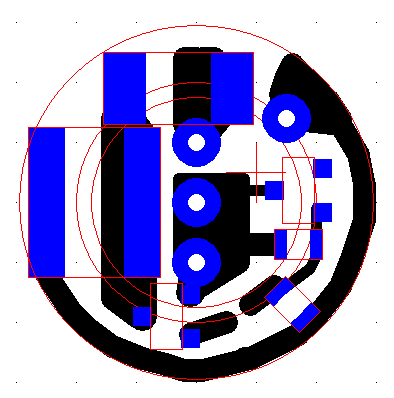

And

this drawing shows how the parts are located on the board. As usual on

my site, you have to work out yourself which part is which.

And

this drawing shows how the parts are located on the board. As usual on

my site, you have to work out yourself which part is which.

Two

holes are for the LED pins. The center hole is to center the negative

connection post, and the last hole has a wire soldered through, that

connects to one of the tantalum caps between the board and the LED, and

has its other end contacting the aluminium housing.

Seen

from the front. I made a reflector-like shape in the aluminium, but

that's really not very important, because most of the light

concentration is done by the LED's built-in lens, which has roughly a

30° opening angle.

Seen

from the front. I made a reflector-like shape in the aluminium, but

that's really not very important, because most of the light

concentration is done by the LED's built-in lens, which has roughly a

30° opening angle.

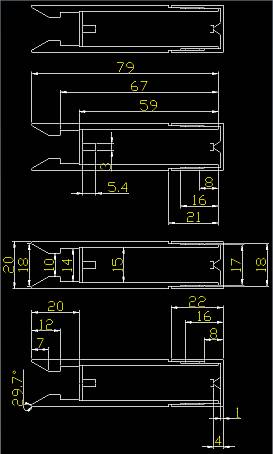

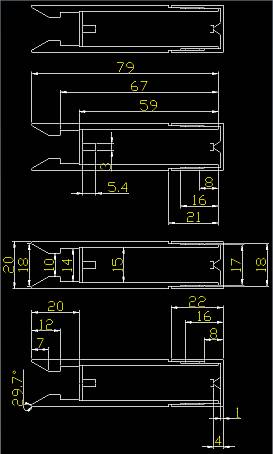

If

you really want to copy my flashlight's aluminium body, be my guest.

Here is the design, with all dimensions. You can click it to get a

larger version. If you prefer, you can also download the file in DXF format, and open it in the CAD program of your preference.

If

you really want to copy my flashlight's aluminium body, be my guest.

Here is the design, with all dimensions. You can click it to get a

larger version. If you prefer, you can also download the file in DXF format, and open it in the CAD program of your preference.

In

this drawing the electronics are only minimally shown: The PCB, the

negative connection post, and the positive cap of the battery.

The drawing is repeated several times, to accomodate all dimensions without making too much of a mess.

Of course you will need a lathe to make this housing.

Note

that one mechanical piece isn't drawn here: A foam rubber ring that

goes inside the cap, and keeps the battery from rattling around when

the end cap is screwed out a turn or two to keep the lamp off.

And

here is the shootout! The left lamp is an old-fashioned Mini-Maglite

that uses two AA cells and a tiny incandescent bulb. On the right,

my LED lamp, using a single AA cell. Both lamps have fresh

batteries in them.

And

here is the shootout! The left lamp is an old-fashioned Mini-Maglite

that uses two AA cells and a tiny incandescent bulb. On the right,

my LED lamp, using a single AA cell. Both lamps have fresh

batteries in them.

This circuit runs the LED at roughly

100mA, which should be safe given its 150mA spec. It draws around

250mA, when the battery is at 1.3V. It works fine both with an alkaline

or a rechargeable cell, and should run roughly 7-8 hours on the

alkaline, and slightly less on a rechargeable.

I'm writing this

page roughly 7 years after having built this lamp. The little lamp has

worked well except for occasional contact problems between the positive

contact wire and the aluminium body. Someday I will improve that by

running a soldered metal foil all the way from the PCB to the positive

side of the cell. And it has had one accident: A Duracell leaked, and

made a terrible mess!

It's a very practical flashlight to

carry around for emergencies, because it's small enough to disappear in

a pant pocket, without being felt, and still bright enough to find

one's way in the dark, work in dark places, etc.

Of

course these days everybody runs around carrying a cellphone, and every

cellphone has a flashlight built in... but this little lamp is a lot smaller and lighter than a cellphone!

Back to homo ludens electronicus.

Flashlights

can be large and powerful, or small and convenient to carry. In

the latter category, flashlights using a single cell are very

convenient, due to their size and usage simplicity. In the old times of

incandescent bulbs, all it took was a 1.2V bulb, placing it in a

reflector and wiring it up with a battery, so that flashlight building

was a purely mechanical task. But in 2015 the device of choice is the

LED, due to its far better efficiency and reliability. And since white

LEDs need around 3V to operate, they require electronics to be used

with a single, cheap AA cell.

Flashlights

can be large and powerful, or small and convenient to carry. In

the latter category, flashlights using a single cell are very

convenient, due to their size and usage simplicity. In the old times of

incandescent bulbs, all it took was a 1.2V bulb, placing it in a

reflector and wiring it up with a battery, so that flashlight building

was a purely mechanical task. But in 2015 the device of choice is the

LED, due to its far better efficiency and reliability. And since white

LEDs need around 3V to operate, they require electronics to be used

with a single, cheap AA cell.

A little round single-sided printed circuit board was made,

which carried all the components, assembled in a very compact way. The

LED, which is a 10mm through-hole type, goes on the non-copper

side, along with the two tantalum capacitors, which make good use of

the space between the board and the LED. All other parts are installed

in normal SMD style on the copper side of the board.

A little round single-sided printed circuit board was made,

which carried all the components, assembled in a very compact way. The

LED, which is a 10mm through-hole type, goes on the non-copper

side, along with the two tantalum capacitors, which make good use of

the space between the board and the LED. All other parts are installed

in normal SMD style on the copper side of the board. As you can see, even this small board has a lot of space left, since the circuit is so simple.

As you can see, even this small board has a lot of space left, since the circuit is so simple. This

shows how small the assembly is. Well, it's a 10mm LED, and the PCB was

made 15mm diameter, the same size to which I turned the inside of the

housing, to fit the AA battery, which may be up to 14.5mm in diameter.

This

shows how small the assembly is. Well, it's a 10mm LED, and the PCB was

made 15mm diameter, the same size to which I turned the inside of the

housing, to fit the AA battery, which may be up to 14.5mm in diameter. Playing with the little lamp, before building the housing.

Playing with the little lamp, before building the housing. Here is the PCB layout. You have to scale it so that the outer diameter of the outer copper arc is 15mm.

Here is the PCB layout. You have to scale it so that the outer diameter of the outer copper arc is 15mm. And

this drawing shows how the parts are located on the board. As usual on

my site, you have to work out yourself which part is which.

And

this drawing shows how the parts are located on the board. As usual on

my site, you have to work out yourself which part is which. Seen

from the front. I made a reflector-like shape in the aluminium, but

that's really not very important, because most of the light

concentration is done by the LED's built-in lens, which has roughly a

30° opening angle.

Seen

from the front. I made a reflector-like shape in the aluminium, but

that's really not very important, because most of the light

concentration is done by the LED's built-in lens, which has roughly a

30° opening angle. If

you really want to copy my flashlight's aluminium body, be my guest.

Here is the design, with all dimensions. You can click it to get a

larger version. If you prefer, you can also download the file in DXF format, and open it in the CAD program of your preference.

If

you really want to copy my flashlight's aluminium body, be my guest.

Here is the design, with all dimensions. You can click it to get a

larger version. If you prefer, you can also download the file in DXF format, and open it in the CAD program of your preference. And

here is the shootout! The left lamp is an old-fashioned Mini-Maglite

that uses two AA cells and a tiny incandescent bulb. On the right,

my LED lamp, using a single AA cell. Both lamps have fresh

batteries in them.

And

here is the shootout! The left lamp is an old-fashioned Mini-Maglite

that uses two AA cells and a tiny incandescent bulb. On the right,

my LED lamp, using a single AA cell. Both lamps have fresh

batteries in them.