Making printed circuit boards at home

using a laser engraver

Printed

circuit boards are just one of many ways to build electronic circuits.

In the industry they are essential, because almost all of the automatic

production machinery is designed to use them. Instead for people

assembling circuits by hand, regardless of whether they are hobbyists

or professionals doing one-of-a-kind jobs, PCBs are entirely optional,

competing against other construction techniques such as dead-bug construction

on a ground plane, mounting parts into a box or chassis, using perfboards or project

boards, etc. Despite the various alternatives, many people choose PCB

construction due to the solidity, reliability, compactness, and sheer

good looks it provides.

Printed

circuit boards are just one of many ways to build electronic circuits.

In the industry they are essential, because almost all of the automatic

production machinery is designed to use them. Instead for people

assembling circuits by hand, regardless of whether they are hobbyists

or professionals doing one-of-a-kind jobs, PCBs are entirely optional,

competing against other construction techniques such as dead-bug construction

on a ground plane, mounting parts into a box or chassis, using perfboards or project

boards, etc. Despite the various alternatives, many people choose PCB

construction due to the solidity, reliability, compactness, and sheer

good looks it provides.

When I began building electronic

circuits, I soon also began making PCBs. At first I designed my boards

with a pencil on a piece of paper, then taped the paper to a piece of

copper-clad board, drilled the holes through the paper and the board,

then removed the paper and freehandedly drew the pads and traces on the

copper. I first tried to use a special felt pen made by Bishop

Graphics, which was supposed to be acid-resistant, but the results were

horrible! The ink of that pen did not fully block the ferric chloride

etchant I used, and the result were very poor PCBs, with seriously

corroded traces and many cuts. So I replaced that pen by a fine paintbrush

and oil paint. This paint was totally acid-proof, delivering shiny

copper traces, but it took at least a full day to dry, and the paintbrush in my

jittery hand produced traces of very unconsistent width. To fix the problem

of long drying time, I switched to fingernail polish, since various other paints I tried did not work

well. For several years I made all my PCBs using this method: Design

with pencil on paper, tape paper to board, drill the holes, remove the

paper, draw the pattern with nail polish, etch, remove the nail polish

with acetone, assemble the circuit. I even made double-sided boards that

way, by designing the board using two colors, and then simply painting

the patterns on both sides of a two-layer copper-clad board.

Over the years my designs became more

complex, and I needed a better resolution. So I began using photographic

transfer. I still designed the boards on paper, then placed a

transparent sheet on that paper, used dry-transfer rub-on symbols

made

by Letraset, Mecanorma and other companies to make the pads and

letters, then used black adhesive tape of various widths to make the

traces and areas. For double-sided boards, two such transparent masks were

made, and taped together. After very careful cleaning of my copper-clad

board, I sprayed it with Positiv-20 photoresist, made by Kontakt

Chemie, quick-dried it in an oven to reduce dust contamination, then

sandwiched the board and transparencies between two glass

plates,

and exposed the photoresist with near UV light. The light source was

always a bit of a problem: The high pressure mercury lamps recommended

in some literature didn't work at all, because they just don't produce

the wavelength required by this photoresist. Low pressure lamps worked,

but gave a diffuse light that tended to undercut the tapes and symbols,

resulting in narrowed traces. The sun at noon on a bright day in summer

was a pretty good UV source to expose PCBs, but usually when I made PCBs

the sky was overcast. At the end I settled for a 150W metal halide

lamp, which worked well enough, but I had to place it so close to the

board that the light fall-off in the corners was significant, causing

some problems of uneven exposure.

After exposure, the Positiv-20 photoresist was developed in a weak

solution of sodium hydroxide (lye). The instructions called for

precisely 7 grams per liter, but didn't mention that this was for pure,

anhydrous sodium hydroxide! Using that amount of the common household lye I could get,

which contains quite a bit of water, doesn't work well. By

experiment I found out that I had to use 10.5 grams per liter, and I

made a precision scale to measure the right amount. After depeveloping, the etching was done in

ferric chloride, just as before, and the photoresist was

removed

with acetone after etching. At this time I also became sophisticated

enough to spray a solder-through lacquer on my boards at this stage. It

used SK-10, also from Kontakt Chemie. Drilling the holes was

the

last stage in this process, and it was very easy and precise, with the

drill bit self-centering in the etched guide holes of

the pads. I

made many boards with this method, for projects such as various radio

transceivers, audio equipment, microcontroller circuits, test instruments, an EPROM

programmer, and many others. The resolution was good enough to pass one

track between pins of an IC.

In 1989 I started working for an

organization, got access to a PC, and with it began the age of CAD for

me. I left the paper and pencil behind, and began designing my PCBs on

the computer. I used several different programs at first, including

professional ones such as the very first release of OrCAD PCB (very

buggy!), Racal Redac (pretty good but user-unfriendly), and more basic

ones, such as smARTWORK, which I liked a lot and used a lot, despite

its somewhat limited capabilities - it could make only two trace

widths! Eventually I replaced them all by TRAX. All of these were DOS

programs, but by this time Windows was beginning to squeeze even into

engineering offices. At the job I eventually began using the

then-current version

of OrCAD for Windows, which was far less buggy than the first OrCAD PCB

for DOS, but also far more complex. The excessive complexity

became a real disease among all sorts of CAD software, so that for

my hobby

activities I began avoiding the big and famous software suites. For

PCBs I began using CiDess. After I retired from the job, becoming

a full-time homebrewer, CiDess became the only PCB design software I'm

using. It's pretty capable, and very suitable for homebrewers, even if

there are always some points that could be improved.

Back

in 1989 the only way I had to produce a high quality printout of a CAD

design was a pen plotter. We were several guys at the job occasionally

making PCBs, so many different combinations of pens and papers were

tried. It was always hard to produce a PCB mask by direct plotting,

that

would transfer well to the photoresist. What tended to work best was

using felt pens on translucent paper, and plotting the design twice to

get better opacity. The other option, of course, was to make a plain

black-ink-on-white-paper plot, take it to a photo lab, and make a high quality

positive transparency from it, using photolithographic material such as

Kodalith or

Agfa Litex, and special high-contrast developer. This also allowed

printing the design oversized, and photographically reducing it to the

exact size, which gave excellent resolution.

Eventually

I

implemented this same process at home. I had bought an HP inkjet

printer (black ink only) to replace my Epson dot matrix printer, and

the inkjet printer produced pretty good contrast, but not enough

resolution to directly print a PCB mask. I was given some expired but

still good Agfa

Litex material and special developer for it, and I put together a

sort-of-Frankenstein-enlarger.

The darkroom was my bathroom, with black cardboard used to seal the

window

against light,

and working in nighttime. Using this method I was able to produce very

high quality PCBs at home, but it took a huge lot of time and

effort for each board I made. Also the fact that I needed to print at

×2 scale to get a good resolution meant that I couldn't make PCBs

larger than half the linear dimensions of a legal-size sheet of paper,

the largest my printer could handle! Also I ran into barrel

distortion problems, caused by the enlarger lens. After some searching

and begging I got a better lens, which solved that problem, at

least.

There

came a time when photoresist spray became

unavailable in my country. And due to new postal regulations, things as

horribly dangerous as a spray can could no longer be shipped by mail,

so I

couldn't import that stuff either. I had to resort to presensitized

board, which is much more expensive, but is also more practical to use,

eliminating the cleaning, spraying and drying steps. I had mixed

experiences with pre-sensitized boards. I got some good ones, but also

some that had very low sensitivity, and some which had been handled in

strong

light, so that the margins (where light can get in under the black

protective film that covers them) had gone bad.

I also got

some boards that worked OK, but had extremely thin copper,

much

thinner than specified. You may guess where I got those from.

Eventually technology advanced, and I

bought a photo quality inkjet printer, that was capable of directly

printing good PCB masks on high quality transparency film (Pictorico

Ultra Premium). So I could get rid of my darkroom, and save several

hours of work when making a PCB. Unfortunately that printer (a Canon) was

extremely finicky, kept making trouble, wasting enormous amounts (by

cost) of ink in needless and seemingly endless cleaning cycles, and

ended its life three days after the warranty ran out,

producing an

error code that according to the information from the manufacturer

means that either the print head, or the mainboard, or the power supply

had gone bad, and that all three of them needed to be replaced at the

same time to fix the printer!

This was such an offense to logic and decency that I have sworn to never

again buy any Canon product.

So, once again I was on the

search for a good, practical process to make PCBs at home. Yes, I know,

well into the 21st century the way to go is to design my boards, create

Gerber files, send them to China, and get my boards factory-made in

professional quality. It's what most electronics builders do. But I kind of like

doing things myself, instead of having them done for me! Also there is

the problem that I live in the woods, quite literally, and there is no

delivery service that would come out here. So, getting anything from

China takes a long time, like several weeks in addition to the time

taken by the Chinese company to make my boards (which is actually

pretty fast), and them travelling to my country. So I wanted to

continue making my PCBs at home.

I

bought a cheap and merry laser printer, to replace the dead Canon

inkjet printer. It was a Brother, the cheapest one I could find. It

prints black only, of course, but does so pretty well, and hasn't given

any trouble at all since I bought it, several years ago. I like that!

In addition to

printing the usual stuff, like assorted love letters, shopping lists

and

schematic diagrams, I had hoped to be able to set up a system for

toner-transfer PCB making. But that never worked for me! I tried

several

different papers, including glossy magazine paper and special

toner-transfer paper, and I also tried different toners, and I tried

all

settings the printer has, which are not many - to no avail. The quality

of the PCBs I got

was horrible, with interrupted traces, corroded copper in any

filled areas, and there was

also

a dimension problem: This printer prints a little too narrow, but it's

not stable, every printout can be a little wider or narrower! In the

direction of paper transport it's quite accurate, but sideways it's

unstable. And the unpredictable part of the error is enough so that on

any but the smallest PCBs it's a problem. For its intended purpose,

printing documents, this slight dimensional inaccuracy is irrelevant,

of

course.

Eventually I

made up my mind that I needed some completely new device to get a PCB

design out of the computer and onto a copperclad board, and hopefully

one that would simplify the whole PCB making procedure to as few steps as possible. And

so I

finally decided to buy a laser engraver to make my PCBs. That was

successful, and the rest of this web page is, at last, about the matter

its title

says!

Making PCBs with a laser engraver

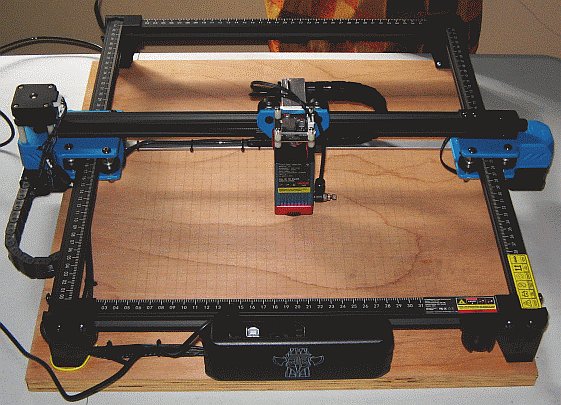

For

those readers who don't know them yet: A laser engraver is a machine

that moves a powerful laser over a work area, under computer control,

modulating its intensity to selectively burn the material at the

desired locations. The one I bought is a Two Trees TTS 55 Pro. It has a blue

diode laser rated at 5.5W optical power, with a lens that minimizes the

elongation of the laser spot. The machine has a working area of about

30×31cm, more than big enough for any PCB I will ever

make. Its

controller uses an ESP32 and runs pretty standard laser engraver

software, so it is compatible with the usual PC software, such as

LaserGRBL. The ESP32 has WiFi connectivity, and there is an SD

card slot, so the engraver can be used either connected by USB to a PC,

or connected over WiFi, or even stand-alone, engraving a board without

requiring any external control after starting. The file can be saved on

the SD card using a PC, or the card can be permanently left in the

engraver, and the files transferred by USB or by WiFi, from a PC or

even from a smartphone. Likewise, the unit can be controlled and

monitored from a PC or a smartphone, using either a dedicated app, or

a web browser, since the engraver provides a web interface. Also the

WiFi module can either connect to an existing WLAN, or it can act as

an access point. It's really very flexible and practical.

For

those readers who don't know them yet: A laser engraver is a machine

that moves a powerful laser over a work area, under computer control,

modulating its intensity to selectively burn the material at the

desired locations. The one I bought is a Two Trees TTS 55 Pro. It has a blue

diode laser rated at 5.5W optical power, with a lens that minimizes the

elongation of the laser spot. The machine has a working area of about

30×31cm, more than big enough for any PCB I will ever

make. Its

controller uses an ESP32 and runs pretty standard laser engraver

software, so it is compatible with the usual PC software, such as

LaserGRBL. The ESP32 has WiFi connectivity, and there is an SD

card slot, so the engraver can be used either connected by USB to a PC,

or connected over WiFi, or even stand-alone, engraving a board without

requiring any external control after starting. The file can be saved on

the SD card using a PC, or the card can be permanently left in the

engraver, and the files transferred by USB or by WiFi, from a PC or

even from a smartphone. Likewise, the unit can be controlled and

monitored from a PC or a smartphone, using either a dedicated app, or

a web browser, since the engraver provides a web interface. Also the

WiFi module can either connect to an existing WLAN, or it can act as

an access point. It's really very flexible and practical.

This

engraver comes prepared to add "air assist", which is simply blowing

fresh air onto the burn spot, to blow away any debris, and keep the

area from overheating. The required air pump is not included, so I

added one. But instead of buying the somewhat pricey pump offered by

the manufacturer of the engraver, I bought just a cheap aquarium airing

pump. Using this air assist is not essential, but seems to help a

little bit.

The manufacturer also offers a handheld controller. I did not buy that

one, since a smartphone can do its job well enough.

As

this engraver comes from the factory, it uses a rather ugly

method

to bring the wires to the moving parts: They are simply looped through

the air, inside flexible plastic slit tubes! They impose some

unstable load

on the mechanism, possibly reducing accuracy through flexing. So I bought one meter of

cable chain, and installed the cables in chain loops, so now they are

well guided. It looks much better, and is technically better too.

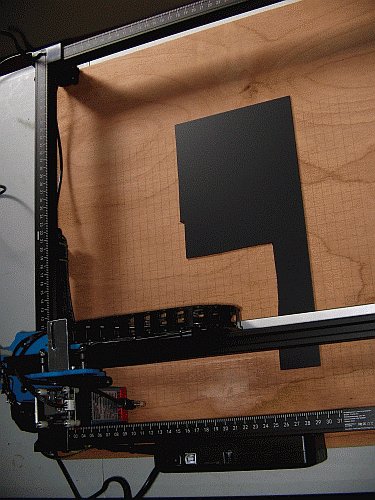

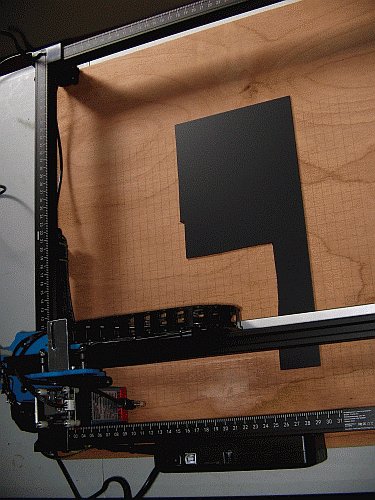

Also

I screwed the engraver onto a piece of 20mm thick, very flat and

straight plywood, and then had the machine lightly engrave a

1×1cm grid over the entire work area. This allows easily positioning the PCBs

at known coordinates, and then commanding the machine to begin

engraving just at the right location.

Also

I screwed the engraver onto a piece of 20mm thick, very flat and

straight plywood, and then had the machine lightly engrave a

1×1cm grid over the entire work area. This allows easily positioning the PCBs

at known coordinates, and then commanding the machine to begin

engraving just at the right location.

There are many laser

engravers on the market, so if you want to set up for this method of

PCB making, you can choose the one you like best. But it's good to

compare specs, to select a suitable one.

Probably all of

the low-cost engravers use blue diode lasers. But there are differences

in the power, and the quality of the lens. Laser diode chips have a

rather long and narrow exit window, so they emit their light from a

surface of that shape. A common lens will deform and soften that image,

focusing it into a small but elongated ellipse of light. This is generally

undesirable, but many of the older/cheaper (as of 2025) laser units

have such lenses. Don't buy one of those, because those elliptical

spots are too long to provide acceptable resolution for PCBs!

The

better laser units instead have astigmatic lenses that produce a

rounder and more defined laser

spot. The advertising of my unit claims that the spot is a tiny square of 0.08×0.08mm,

but that's wishful thinking - it's still a bit elliptic! But it's small

enough to allow making even the finest PCBs, and that's what counts.

Another confusing matter is the power rating of these lasers. There are

three ways in use to rate the power:

- The optical power emitted (nominally 5.5W in mine)

- The electrical power consumed by the laser diode (roughly 15W in

mine)

- The electrical power required by an old-style carbon dioxide laser to

produce the same optical power (about 40W in mine)

So

when you compare specs, you absolutely need to know which "standard" is

being used to rate the power! Optical power is what counts. The more,

the better, but really high power lasers are an advantage only if the

modulation is fast enough to burn at a high speed and still get good

enough resolution.

When you go

shopping for a laser engraver, I suggest that you look at how stiff and

accurate the rails, wheels, and traction systems are. Mine uses plastic

wheels on extruded aluminium rails, and rubber belt drive. That works,

but is NOT ideal. Polished steel rails, with spring-loaded steel

wheels, and ball-bearing-screw-type drive, would be much better. And

also much more expensive, of course...

How the method works

The

basics are quite simple: The copper-clad board is coated with

black

paint, and allowed to dry. The PCB is designed in CAD, or

scanned from a

magazine, or whatever.

The goal is to end up with a precise raster image of the copper

pattern, in a file format like PNG, GIF, or BMP. Then a

converter program is used to turn this image into a long list of G-code

instructions, which the laser engraver can understand. The G-code file

is loaded into the engraver's SD card, or it can simply be

streamed to the engraver from a PC or smartphone. The painted (and well

dried!) board is placed in the engraver, the laser focus is

adjusted, the origin

(home point) is set, and then the engraver does its job. It will

burn

the paint in those areas where we need to remove copper. After

it's

finished, the burned paint residue needs to be cleaned away,

then the board is etched in

ferric

chloride or any other copper etchant. Then the remaining

paint is removed, optionally a solderable lacquer is applied, the holes

are drilled, and that's

it!

Since the devil lays in the details, let me now walk you through each

step.

Board material

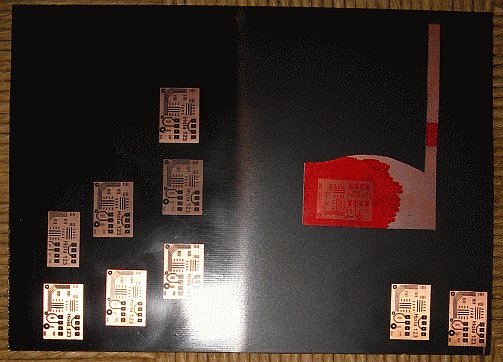

It's a good idea to buy a reasonably large piece of board,

or several pieces, and clean and paint them all at once. They can be

stored for as long as wanted, and so there will always be a supply of

ready-to-use, painted, dry board at hand.

Copper-clad board comes in many types:

-

Base material: Most common and available are FR1 and FR4. Both are fire

retardant, but FR1 is basically paper impregnated in phenolic resin,

while FR4 is fiberglass impregnated in epoxy resin. FR1 is cheaper and

more gentle to the drill bits, while FR4 is stiffer, stronger, has

better copper adhesion, better insulation, and lower dielectric loss at RF. When I

was a poor student I used FR1, but since I began earning my own money I

only ever use FR4.

Other materials exist, and are common in

microwave work, high power electronics, and other special

areas,

but are not easily available to homebrewers in small quantities.

- Thickness: 1.4 to

1.6mm is by far the most common, and is a good all-round thickness. 1mm

is becoming somewhat common. Much thicker and much thinner boards

exist, but are rather hard to find.

- Number of copper layers:

You can choose between single-sided and double-sided board. If you are

like me, you will have good use for both of them, so it makes sense to

buy some of each.

- Copper thickness: The standard copper layer

thickness in the good old times was about 35µm, known in the USA as "1

oz copper", meaning one ounce of copper per square foot of board area. This

is a good thickness for typical PCBs. Instead for PCBs on which some traces

need to carry a high current density, 70µm copper thickness (2 oz copper) is better.

And board material intended for being used in processes that create

plated-through holes typically has only 18µm of copper thickness, or

even less, since this thickness will increase by galvanic deposition

when plating the holes. Such "1/2 oz copper" boards are not advisable

for use in processes that don't add more copper, but a

lot of such board material is currently available, simply because it's

cheaper than board having a normal copper thickness! So, be sure to

check that the board you are buying does have at least 35µm copper on

it, and don't buy from websites where you are likely to get cheated!

In

addition to all this, of course there are various qualities. Some boards

have a nice smooth finish, while other boards are quite irregular, with

the fiberglass fabric structure showing up through the copper.

See the photo at the beginning of this page for an example of that!

Such roughness is not a functional problem, but a smooth board looks

nicer.

Some fiberglass boards are little fiber and much epoxy,

while others are the other way around. That makes a large difference in

stiffness, since glass is a lot harder than epoxy resin. Also the

dielectric constant and the losses vary between different boards.

Anyway the

good news is that all board material available will basically work. The most

important choices are between FR1 and FR4, and between single-sided and

double-sided board.

Before the board is painted, it should

be cleaned. Although the laser engraver PCB process is hugely more tolerant

of

dirt, grease and oxide than any photoresist-based one, a clean board

looks nicer and solders much more easily than a dirty one.

My

way of cleaning the board has two parts. The first is trying to not get

it dirty! Touching it with bare fingers will deposit skin acids on the

board, and the copper will start tarnishing in a matter of a few days.

Later one can admire one's fingerprints, nicely reproduced in black oxide on

copper background. Try to avoid that!

The second step is removing

light surface tarnishing by means of fine steel wool. Very

little pressure is used, or the copper will end up deeply

scratched. The game is all about wiping the surface in

both orientations, from all sides, not forgetting the borders and

corners, in quick moves at light pressure. That's all! Then all

steel wool debris and other loose dirt is blown or swiped away, and

it's done.

Paint

Now comes

the matter of paint. That's another big chapter! Much has been written

about what's the best paint for laser engraving. Enamel or lacquer,

what color, matte or glossy? Spray, or brushed, or spin-coated? I will

try to bring some sense into that.

First

let's

consider what paint is, really! What comes in a paint can is mostly a

mix of solvents. In some paints most of the solvent is water, while in

others there is no water at all. In the solvent mix is a smaller

amount of some synthetic resin -

think of it as a plastic, or plastic precursor, dissolved in those

solvents. Also there is a

tiny amount of finely divided pigment. Think of that as microscopic

dust grains of the desired color, possibly of several colors.

That's all

that

basic paint needs! But there are usually some additives. In high gloss

paints there are additives to

smoothen out the surface while drying, while matte paint contains a

significant amount of some coarser, inert material, such as talc or

silica. Think of it as very fine sand. Special paints, such as rust

protection or rust converter paint, contain specific chemicals for

those functions, and so on.

When the paint dries, the

solvent evaporates, and the resin polymerizes. What's left, in glossy

paint, is a clear plastic layer, in which there are zillions of little

colored particles. In the case of matte paint, the result is rather a

layer of fine "sand", with the colored particles lodged between

the sand grains, and some plastic acting as glue to hold it all

together.

Of course there are a lot more details regarding

paint, but this simplistic approach is all we need to select a good

paint for PCB making.

When the laser fires at the paint, the

plastic lets most of the light pass, but the little specks of pigment

absorb the intense laser light, and get very hot. What we need is that

these pigment particles burn the surrounding plastic, rather than getting burned

themselves! So that defines the two requirements for the pigment: It

needs to be of a color that efficiently absorbs blue light, and it

needs to be heat-resistant. Any color in the range of brown, red, orange,

yellow and green will absorb blue light well, as long as the color is

saturated. Black pigment will absorb all light, of course, including

blue. So what we need to avoid is blue paint, and anything containing

blue - which includes white, gray, and any unsaturated colors. That's

easy! But the heat resistance of the various pigments is

mostly

unknown to us. With one exception: Almost all black paint uses carbon

as the pigment, and carbon is highly heat resistant!

Bingo! Black

paint is fine, and since it's also widely available, and easy to see on

copper, we don't need to look any further. We use black!

The

next question is whether to use glossy or matte paint. Some people have

written on the web that it has to be matte paint, because glossy paint

reflects too much of the light. That's incorrect! In fact matte and

glossy paints reflect roughly the same fraction of the incoming light -

the difference is rather in how

they reflect it. While glossy paint reflects light in the same

orderly way a mirror does, with the exit angle being equal to the entry

angle,

matte paint scatters the reflected light in all directions. For PCB

engraving purposes, that's not a very significant difference.

To

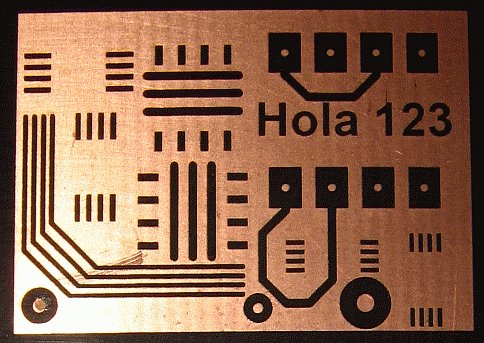

find out whether matte or glossy paint works better, I took a piece of board material and spray-painted one half

with glossy black acrylic paint, and the other half with matte black

acrylic paint. Both paints are of the same manufacturer and type. Then I burned a little test board design into each paint,

adjusting the parameters to get optimal results. What I found was

that matte paint is very forgiving: My first attempt turned

out

pretty good, and the second one was perfect. The glossy paint instead

was quite finicky, and I had to make 7 attempts before I found settings

that would produce perfect results. But then the resolution of the

glossy paint was better, and it doesn't need manual cleaning after

burning! Instead when using matte paint, most of the paint components

stay on the board after engraving, and need to be brushed and wiped off.

To

find out whether matte or glossy paint works better, I took a piece of board material and spray-painted one half

with glossy black acrylic paint, and the other half with matte black

acrylic paint. Both paints are of the same manufacturer and type. Then I burned a little test board design into each paint,

adjusting the parameters to get optimal results. What I found was

that matte paint is very forgiving: My first attempt turned

out

pretty good, and the second one was perfect. The glossy paint instead

was quite finicky, and I had to make 7 attempts before I found settings

that would produce perfect results. But then the resolution of the

glossy paint was better, and it doesn't need manual cleaning after

burning! Instead when using matte paint, most of the paint components

stay on the board after engraving, and need to be brushed and wiped off.

Where does this behavior come from? I think it's easy to explain,

considering the structure of each paint layer:

With

glossy paint, each little speck of carbon absorbs laser light, gets

hot, burns or evaporates the plastic around it, and as it's freed up,

it takes flight, going away with the stream of plastic vapor or smoke.

When only a very thin layer of paint is left, there are ever fewer

carbon specks remaining, so light absorption gets worse and worse,

hindering the burning of the last few microns of plastic that remain.

If I turn up the laser power like crazy, the paint around the laser

spot begins melting, and it flows out, re-covering the

surface already left behind by the laser! So it's hard to find the

exact right dose of laser energy.

The matte paint instead is

different: When a speck of carbon has burned all the plastic around it,

there is still the "sand" (talc or silica). This material is also

heat-resistant, and won't burn. So the carbon specks are trapped, and

can't take flight as easily as in the case of glossy paint. So they

keep absorbing energy from the laser, heating the remains of the paint

layer as long as the laser spot is

there, burning the plastic right down to the copper. The "sand" and the

carbon pigment remain in place, but are easy to clean away manually.

And

of course, the relatively coarse grain structure of the matte paint's "sand" causes

slightly worse resolution than with glossy paint, but it's still plenty

good enough. So my decision was: Matte black paint is best.

The

next decision: What resin should the paint be based on? Many resins are

used to make paints: Vinyl, acrylic, alkyd, polyurethane, polyester,

even cellulose acetate. I tried acrylic, alkyd, and cellulose-based

paints. Both blacks on my test board in the photo are acrylic paints, while

the red paint on the little scrap of board is cellulose-based. On the

back of that same board I tried flat black alkyd paint. They all seem

to work about the same, in terms of results, even if in the single test

I did with the cellulose paint the laser didn't burn through to the

copper, that red paint being glossy. But there are still some practical

differences: The alkyd paint smelled the worst during burning, and is

also the slowest-drying one, and more expensive than acrylic paint. For reasons of low

cost, quick drying, and low odor, I selected the acrylic paint as the

best option. I didn't try others, like polyurethane, because they are

supposed to be more heat-resistant, which is precisely what we don't

want!

Lastly: Spray paint, or brush the paint on, or use an

airbrush, or spin-coat the boards? For reasons of simplicity and

convenience, and given the wide tolerance the laser engraving process

has for uneven layer thickness, I settled for spray paint.

So my

recipe is: Use the cheapest available matte black spray paint available

in the local hardware store. And this is also the advice given by other

people who are using this method to make their PCBs, even if they

aren't as verbose as I am in explaining why! In my case the chosen paint

was

"Super Coat" acrylic enamel spray paint, made by Sherwin Williams in Brazil.

I

probably don't need to describe how to spray-paint a board... But just

in case: Place the board on a clean surface that you can make

dirty. Begin spraying outside the board area. Move over the

board

in lines, doing the reversing outside the board area. Spray until the

board is completely covered, totally black. Release the button outside the

board area. A good spraying distance is about 25cm. Since acrylic paint

dries fast, a longer distance can cause half-dry paint particles

to land on the board, making the layer rough and irregular.

Acrylic

paint dries in just about 15 minutes, but takes about a day to fully

harden (polymerize). Don't rush it. Store painted board material with

smooth separators between boards, to avoid scratching the paint. I

painted several pieces of single and double-sided board material I had

in stock, and stored them.

Board design:

As already mentioned, I currently use CiDess software to

design my PCBs. It handles single and double-sided boards, through-hole

and surface mounted parts, the SMDs can go on either side of a board,

it shows 3D previews, and it's quite usable after some practice. New

parts can be defined as required. Component placing and trace routing is all manual. A very important feature is that this

software prints guide holes in each pad, which is a big help at the

time of drilling. I would never use PCB software that can't

print guide holes!

CiDess always makes guide

holes proportional to the size of each pad. But I prefer having the

same small size of guide hole on all pads. That's easy to do, by

placing small pads on top of any large pads. The smaller guide hole of

the smaller pad will prevail.

One bad point is that CiDess can't make

arbitrary copper planes. Just a basic ground plane. It doesn't have a

fill function for arbitrary planes. So when an arbitrary copper plane is needed, I make a

trace that defines the contour, and then fill the area with wide

traces, to blacken it completely. Any guide holes in that black area

are still printed. That works fine, but is more work than just defining a contour and then pressing a fill button.

CiDess does not produce Gerber

files. It can

either print the layout directly on the local printer, which was very

useful to me when I printed masks for the photographic

process, or it can export the layout as BMP or GIF images, which is

what I use now. When exporting such a raster image, CiDess allows

selecting the scale in 13 steps, from ×1/4 to ×10. Each full

step

is 120 DPI, so the maximum scale of ×10 results in a raster image that

has the exact correct size when printed at 1200 DPI. To get the maximum

resolution and quality the program can deliver, I'm using 1200 DPI even

for boards that don't really need that much resolution, just for the joy of seeing a precise PCB!

Note

that the resolution to be used depends quite a bit on the laser spot

size of the engraver. If the spot is oval rather than circular, it also

depends on whether the laser scans along the long or the short axis of

that oval. Also it is possible to widen the spot by slightly defocusing

the laser, to burn wider lines and thus scan a large PCB in far less

time, but this requires a pretty powerful laser to still burn the paint

completely. So I suggest that if you want to try this method, with a

laser engraver roughly similar to mine, start out at a resolution

between about 600 and 1200 DPI, and go from there. 600 should be good enough

for through-hole PCBs, while SMD PCBs, specially for the 0.5mm pin

pitch ICs, will need 1200 DPI or better.

Whatever PCB software is used, it's necessary to end up with a two-color raster image of each

copper layer, where black is copper and white is no-copper, at a known

resolution, not mirrored (so that any text printed in copper is legible

in the image). General-purpose image editing software such as

IrfanView can be used to invert colors, invert or mirror images, crop the images, etc,

if necessary. With CiDess and my G-code converter, no such editing is required.

G-code conversion

Once

we have a raster image of the layout, it needs to be converted into

G-code, which is the language laser engravers understand. There are

several programs that will do this, both free and commercial ones. I

don't know about you, but I don't like paying for software! Instead I

prefer to use free software, and if none is available that does what I

need, write it myself and make it available for free. So I tried

the well-known and much-used LaserGRBL software, which in principle

does have all the features needed to take a raster image and

engrave it. The only problem is that LaserGRBL is aimed more at

artistic engraving, such as burning a photo of a landscape onto

a piece of wood. When trying to burn a

high-resolution PCB, LaserGRBL quickly

hits its limits, particularly in combination with inexpensive engravers

that have a lot of backlash, elasticity and friction in their moving

parts. The quality I got was unacceptable.

There are two

fundamentally different ways to burn such an image. One is to move the

laser to the beginning of an area that needs to be burned, turn it on,

and then move it smoothly around in that area, like a farmer mowing a

field, making turns, lines, whatever, to cover the entire area in the

least possible time, without passing twice over the same spot. Then

turn off the laser, move to the next area to be burned, and begin

burning there. This method requires moving the laser in all directions

while

burning, and that will only be accurate if all the structures, rails,

wheels, motors, belts, etc, are stiff and precise enough, and if the

motions are slow enough so that inertia and flexing are irrelevant. In

low cost

laser engravers the mechanisms are stiff and precise enough to engrave

a picture

that will be viewed from one meter distance, but they are neither stiff

nor

precise enough to engrave a PCB in that way, particularly not one

intended for SMDs.

So

we need to resort to the other method: The laser scans the image area

in lines, covering the whole width of the PCB plus some margins for acceleration

and deceleration. The laser is pulsed on and off to burn the

paint where it should, and leave it intact where we want to end up with

copper. Burning is done only while moving in one direction. During retrace the laser

is always off. This is very much like the sweep of a CRT TV or monitor. With

this method, backlash doesn't matter at all, and lack of stiffness

matters very little, because the laser head accelerates outside the PCB

area, stabilizes its motion, and then just moves smoothly at constant velocity while engraving.

But

LaserGRBL doesn't have this mode! It can indeed do scan lines, but it

cannot accelerate outside the image area. Some commercial programs have

that mode, but I like free software...

So I wrote my own program

to do the G-code conversion. It's just a very basic (literally, written

in BASIC language!) command-line program, but does the job quite well.

It directly reads the raster files exported by CiDess, or any other PCB

software that can do that, from the PCB program's directory, handles

all the conversion, and leaves the G-code file in the directory defined

by the user. A configuration text file allows setting the source and

destination directories, DPI, laser power, burning speed, overscan

width (for acceleration), and it also allows setting correction

parameters to compensate for the effective size of the laser spot.

These parameters are separate for X and Y, so that the dimensions of an

elliptic laser spot can be correctly compensated for.

If you

want to make PCBs with a laser engraver, and you want to use my

program, you are welcome. Just download it, unzip it into a directory

of your choice, edit the .cfg file to reflect your needs and

preferences, and send the .bat file to the desktop or into your start

menu. To use the program, you click that icon, enter the filename of

your PCB raster file, and the program will do the conversion and give

you a report.

Raster image to G-code

converter

The

configuration parameters in the provided .cfg file are the ones I

currently use. Most likely you will need to modify some of them. The file

includes some hints and instructions.

If you have the bad idea

to feed a color or grayscale image into this converter, or if you use a

lossy-compressed file format like JPG, the program should try to sort

all colors or gray levels so that the darker half is considered copper,

and the lighter half no-copper. I don't know how well that would work,

since part of the functionality is in an external library my program

uses. Better avoid it, and use only lossless black/white image formats.

Laser engraver setup

Laser

engravers support a set of configuration commands. LaserGRBL and

similar programs can be used to access the machine's configuration, and

change the parameters as needed. Most parameters are

properly

set at the factory, but there is one that absolutely needs to be

changed, to make good PCBs! That's the laser PWM frequency, parameter

$28. The factory setting is 1000Hz. At that low frequency, and any

power setting below maximum, the laser pulses slow enough to results in jagged

traces! See this photo of a small test PCB, and pay attention to the

vertical lines, particularly the ones at the very left. You will see

some of them having zigzag borders. This is an interference pattern

between the laser head motion frequency and the laser's PWM frequency.

Laser

engravers support a set of configuration commands. LaserGRBL and

similar programs can be used to access the machine's configuration, and

change the parameters as needed. Most parameters are

properly

set at the factory, but there is one that absolutely needs to be

changed, to make good PCBs! That's the laser PWM frequency, parameter

$28. The factory setting is 1000Hz. At that low frequency, and any

power setting below maximum, the laser pulses slow enough to results in jagged

traces! See this photo of a small test PCB, and pay attention to the

vertical lines, particularly the ones at the very left. You will see

some of them having zigzag borders. This is an interference pattern

between the laser head motion frequency and the laser's PWM frequency.

Increasing the PWM frequency to 10000Hz solves this problem.

Some

other parameters might be of interest. Parameter $50 sets the WiFi

mode, with 0 being off, 1 making the machine act as an access point,

and 2 making it try to connect to an existing WLAN. When operating as

access point, parameter $51 sets the network name, and $52 sets the

password. Instead when connecting to an existing WLAN, parameters $53

and $54

set the network name and password.

Parameter $100 sets the steps per millimeter for X, and parameter $101 sets it

for Y. These come factory-set to the nominal values for the machine, which are

precise as long as the belts of the machine have exactly the correct

tooth pitch. If the belts are too tense, or too loose, they stretch or

contract a little, and that makes the dimensions of the engraved PCBs slightly

imprecise. So an important part of the initial setup is to check the

precision of X and Y dimensions, and if it's not good enough, either

tensing or loosening the relevant belt a little, or adjusting these

configuration parameters. They accept decimals, even if the nominal values are usually integers.

All the other parameters are usually fine as they come from the factory.

After

changing any parameters, there is a command that has to be given to

save the changed parameters into non-volatile memory. After that, the

parameters will stay, and don't need to be checked for every PCB.

I

also made a hardware adjustment: The X motor of my engraver ran

extremely hot. The operating currents for each motor are adjustable by

means of tiny potentiometers inside the controller. I reduced the

setting until the X drive began losing steps when accelerating, and

then increased it to a middle point between that limit and the original

position. At that setting the motor runs cool, and no steps are lost.

Engraving

This

is my workflow to engrave a board: First I set up the engraver on a

desk in my guest room, because in my office/workshop/radio room I simply never have

enough free desk surface. The guest room is usually unoccupied, due to a severe and chronic lack

of guests. Accessing the engraver's web interface over WiFi through my

LAN from my PC, I upload the G-code file created by my converter

program.

This

is my workflow to engrave a board: First I set up the engraver on a

desk in my guest room, because in my office/workshop/radio room I simply never have

enough free desk surface. The guest room is usually unoccupied, due to a severe and chronic lack

of guests. Accessing the engraver's web interface over WiFi through my

LAN from my PC, I upload the G-code file created by my converter

program.

Then I place the painted board on the work surface,

check/correct the laser focus with the tool that comes with the

engraver, and then carefully align

the board to the grid. It can be placed anywhere in the workspace, and

it's a good idea to place each board at a somewhat different location,

in order to wear the rails and belts more evenly. To keep the laser

from burning the wooden base, and to allow precise finishing of the

PCB's borders, I place my board so that the lower left corner of my PCB

will be about 2mm inside of the raw board's edges. With single-sided

boards, alignment isn't critical, the only goals are that the whole

design fits on the board, and not too much board area is wasted. With

double-sided boards instead, precise alignment is needed, which can be

done by cutting the board to a precise size, including a small but

precisely known margin, and aligning it very well to the grid each

time. It's also possible to drill two holes through the board,

symmetrically and outside the PCB area, and drill them all the way into

the wooden base, or into another piece of wood that is then placed on

the work area. Then the board can be pinned down, the first side

engraved, then it's flipped over and pinned down in the exact same

location, and the other side is engraved.

The

grid I engraved on my plywood base has its origin 1mm up and right

from the left lower corner. Since this engraver has no init switches

nor sensors, I turn off the engraver and manually push the laser head

fully into the left low corner, where it is shown in this photo, and

then I switch the engraver on. Then I access the engraver from my

smartphone over WiFi, and use the commands provided to move

the

head 1mm up and right. Now I have it at the origin of my grid. Then I

use the commands to move the head to the lower left position of my PCB,

as counted on the grid lines. I visually

check that now the laser head is centered in X and Y on the grid lines

where I want my PCB to begin, to rule out any gross mistakes.

The G-code

my converter program produces assumes that the left low corner of the

total

scan area, including the overscan, is the home (reference)

position. So

I need to move the laser head left, by just as much as the width of my

overscan area, defined in the configuration file of my converter. Since

I use 5mm, I move the head 5mm left, by the interface

commands. Now the head is exactly at the beginning of the desired scan

area, and I set the new home position there, by the interface

command. To check that it is correct, I move the head away

a random amount, by interface commands, then command it to

return

to home, and visually check that it returned correctly. After that I

command the machine to begin engraving the G-code file of my new PCB,

stored on its SD card. Then I can walk away and let the machine work. I

can check the progress on the smartphone. A modern world this is...

Even

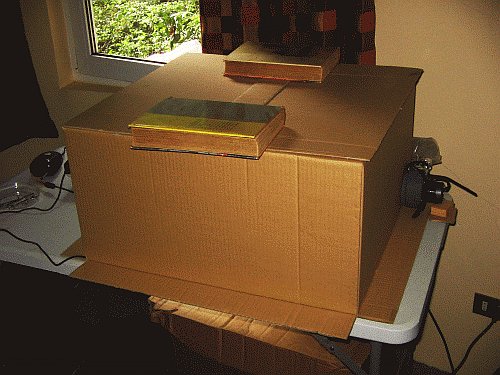

if acrylic paint proved to be the least smelly while burning, it's

definitely not odor-free. At first I simply opened the window and

closed the door of my guest room, but the smell tends to cling to the

room, and is detectable even the next day. So I crafted this fancy

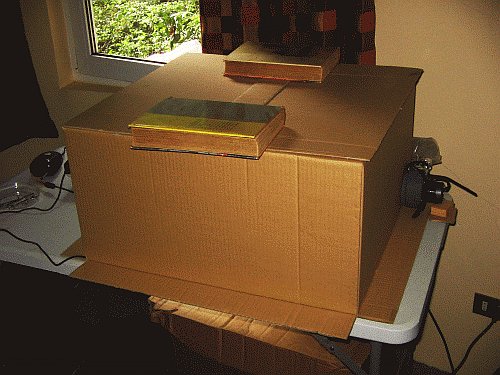

smoke hood from an old cardboard box and some hot-melt glue. I turned the

box inside out, so that all the advertising for its original contents

isn't visible. It looks far more decent that way!

Even

if acrylic paint proved to be the least smelly while burning, it's

definitely not odor-free. At first I simply opened the window and

closed the door of my guest room, but the smell tends to cling to the

room, and is detectable even the next day. So I crafted this fancy

smoke hood from an old cardboard box and some hot-melt glue. I turned the

box inside out, so that all the advertising for its original contents

isn't visible. It looks far more decent that way!

The top

cover is easily lifted off, to access the engraver. To keep it in place and reasonably well

sealed, I use some honorable, ancient and heavy literature. This

is vivid proof for the fact that books are still useful, even

in

the age of the Internet!

There is an exhaust fan installed on

the box, visible on the right side. A lightweight and flexible hose

connects to it, and sends the smoke out of the slightly ajar window.

Air

enters the box only through the imperfect seals between the

box, the

cover, and the desk. This creates an extremely small

underpressure in the box, which is enough to completely prevent

any smell from escaping it.

The

engraving process is slow. I need to stress that point! This

PCB production method is unsuitable for producing large amounts of PCBs, due to its

slowness. But it's perfectly suitable for homebrewers who just make one

occasional board every now and then. While the engraving process is

slow, it's totally automatic, and requires no attention, except that

somebody should always be around and ready to act in case anything goes

wrong. Should the machine fail, the laser could conceivably end up

turned on and pointing at a fixed spot of the wooden base, possibly

setting it on fire! Since I'm just one room away while the engraver is

working, that's not a problem for me, but if anybody needs to let such

an engraver work completely unattended, for example overnight when

everybody sleeps, it might be a good idea to use a metal base instead

of a wooden one, so that nothing can catch fire, even if a

malfunction happens.

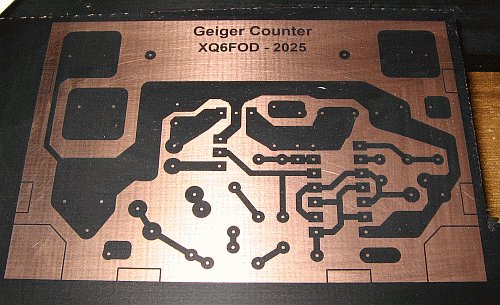

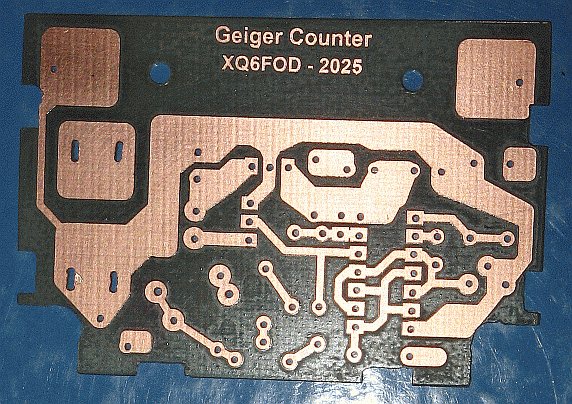

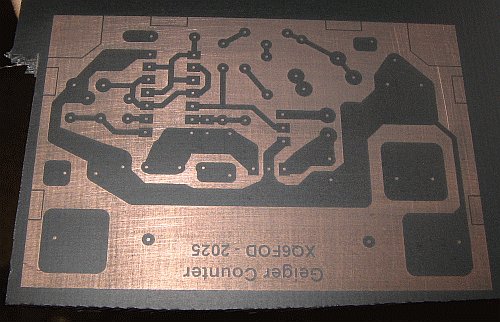

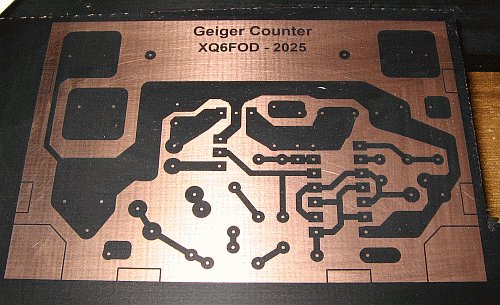

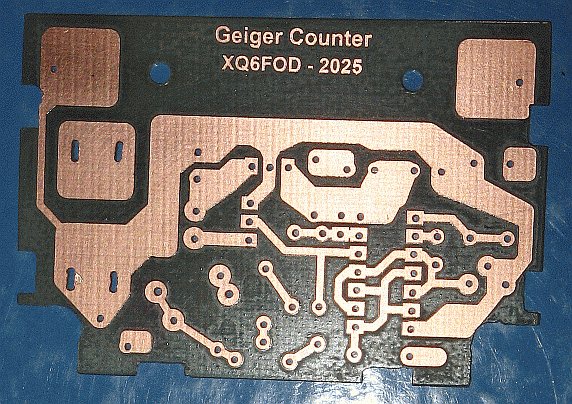

The Geiger counter PCB shown in this page

measures 73×50mm, and took roughly 50 minutes to engrave.

Since

the time needed is roughly proportional to the PCB area, an Eurocard

might take slightly less than three and a half hours, and a

really

large board might well take a full day. I have my system configured to

engrave at a speed of 6000 millimeters per minute (that's the unit used

by this engraver). So, to scan the 73mm width of the board, plus the

10mm total overscan, 0.83 seconds are needed per line, plus some small

time for acceleration. The retrace is faster than that, and happens at

the acceleration and maximum speed configured by the

manufacturer of the machine. These are an acceleration of

2500mm/s², and a speed of 30000mm/min, again using the units set by the

manufacturer of the machine. All this results in a total time of

slightly over one second per complete line, including the retrace. Since I

engrave the boards at 1200 DPI, that's roughly 0.021mm per line. With

this board measuring 50mm in the Y dimension, it requires about 2362 scan

lines. At a little over 1 second each, there we have the roughly 50 minutes

it took.

Due to the time used to scan the overscan area at the

sides of the PCB, and the acceleration and deceleration, it's faster to

engrave a given board with its long axis in the X orientation, rather

than in Y. So any board that was designed with its long axis in Y

should be rotated by 90°, to make the engraving process as fast as

possible for the parameters used.

Out of fear of shortening the

life of my laser diode, I set the laser power to 75% of the maximum.

This might not be necessary, considering that anyway the laser is off

during retrace, also over the overscan areas, and of course when moving

over any areas where the copper is to be preserved. To get maximum

engraving speed it would be wise to set the laser to 100%, and try what

is the maximum speed at which the paint is still burned well

enough. Also the resulting accuracy needs to be watched, because at a

higher speed there will be more imprecision coming from the timing

accuracy limit of the laser on/off control.

At the current stage of my

life, electronics is a hobby for me, not a job anymore, and so I just

let the machine take the time it needs to do the job well.

Cleaning the paint residue

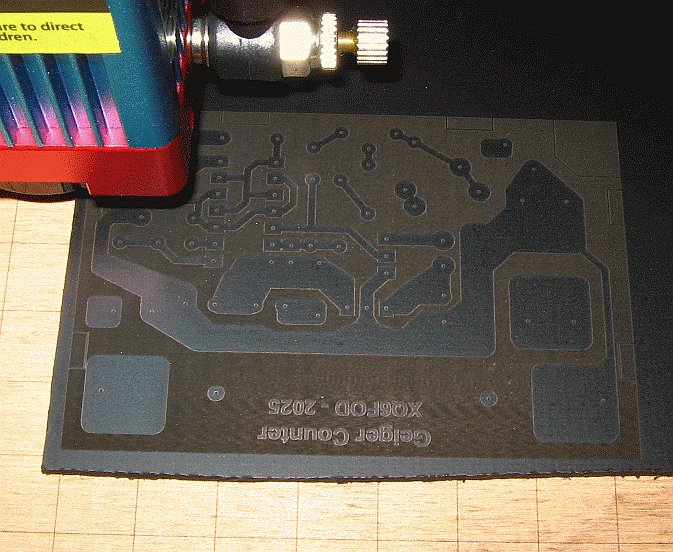

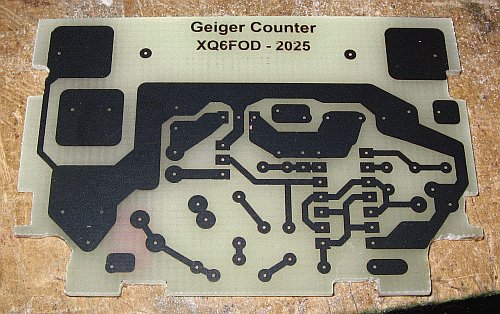

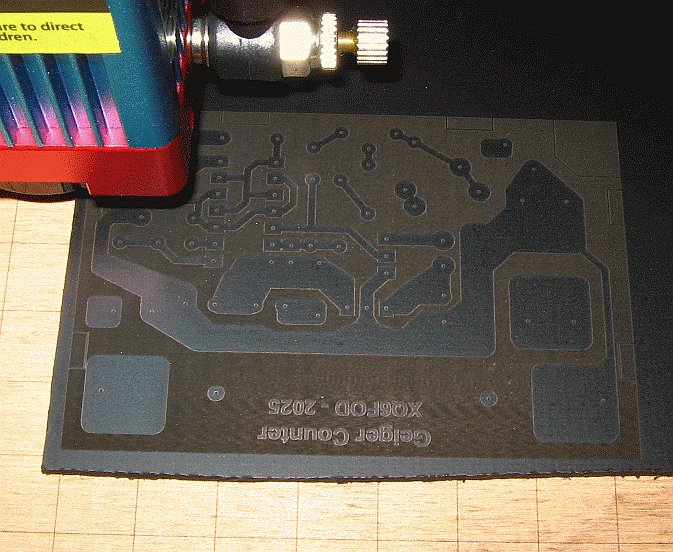

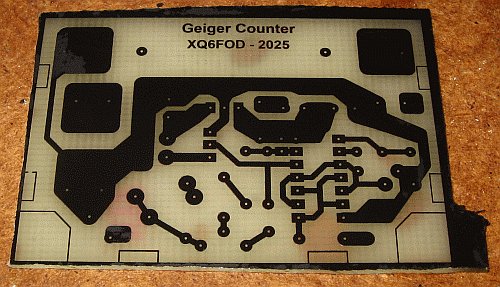

This

is how the board looks when engraving has finished. All of the paint

still seems to be there, and it just looks roughened in the areas where

the laser burned it. But make no mistake! The laser thoroughly

destroyed the paint at the places it hit. The talc powder and the

carbon pigment particles are still there, but only very loosely bound

to each other and the board, by charred residues of the resin.

This

is how the board looks when engraving has finished. All of the paint

still seems to be there, and it just looks roughened in the areas where

the laser burned it. But make no mistake! The laser thoroughly

destroyed the paint at the places it hit. The talc powder and the

carbon pigment particles are still there, but only very loosely bound

to each other and the board, by charred residues of the resin.

This

photo also shows quite well how the lower left corner of the PCB ended

up exactly where I wanted it, at a crossing of two grid lines, leaving

an adequate margin on the raw board. You can see better than in other photos how I aligned the board to the grid.

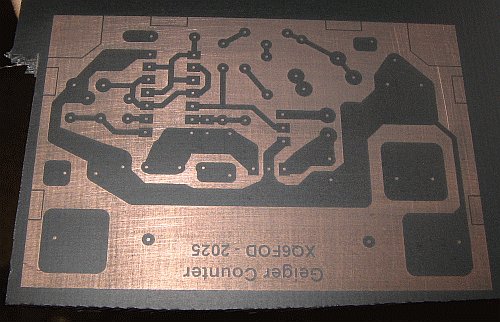

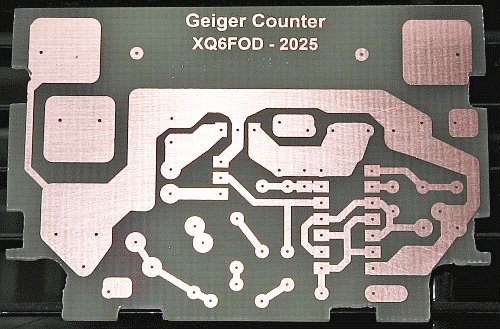

This

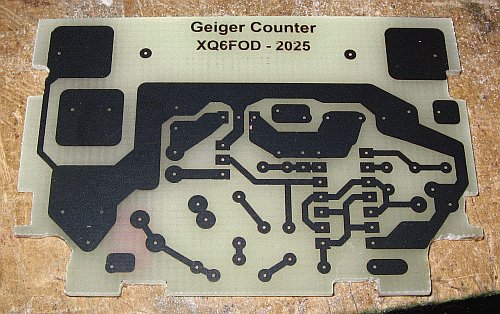

is how the board looked after brushing off the loose paint residue with

a paintbrush. A soft toothbrush can also be used, with care to not

damage very narrow traces.

This

is how the board looked after brushing off the loose paint residue with

a paintbrush. A soft toothbrush can also be used, with care to not

damage very narrow traces.

Some paint residue sticks to the copper a little more firmly, and needs

to be removed in a second cleaning step.

The

second cleaning step is wiping the board with a piece of paper towel

soaked in alcohol. I tried both ethyl and isopropyl alcohol,

and

both seem to work well. Water instead did not work well, showing that

some slight solvent action is required. I suspect that the laser's heat

thoroughly depolymerizes the acrylic binder, so that what's left is

soluble in alcohol, while the non-lasered paint remains polymerized and

insoluble in alcohol.

The

second cleaning step is wiping the board with a piece of paper towel

soaked in alcohol. I tried both ethyl and isopropyl alcohol,

and

both seem to work well. Water instead did not work well, showing that

some slight solvent action is required. I suspect that the laser's heat

thoroughly depolymerizes the acrylic binder, so that what's left is

soluble in alcohol, while the non-lasered paint remains polymerized and

insoluble in alcohol.

To make sure that no thin film of paint

remains on the copper that will be etched away, a good test is to take

a multimeter that has a good, instant-reacting continuity beep

function, connect one test lead firmly to the copper, and very lightly slide

the other test lead over the copper surface, in several areas. It

should produce a continuous beep. If the beep is

intermittent, probably more cleaning with alcohol is needed,

or

the board wasn't lasered well enough.

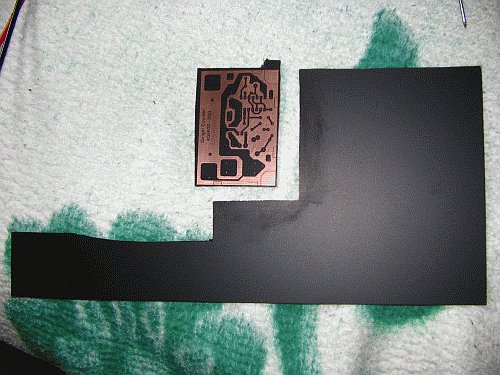

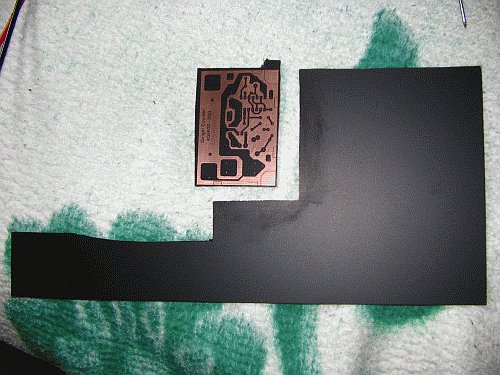

I

cut my PCB from the raw board only after confirming that it's good and

ready for etching. In case the lasering went wrong, I would simply try

again in another corner of the raw board, with corrected settings, and

later on remove the paint from the rest of the board, and repaint it.

That way no board material goes to waste.

I

cut my PCB from the raw board only after confirming that it's good and

ready for etching. In case the lasering went wrong, I would simply try

again in another corner of the raw board, with corrected settings, and

later on remove the paint from the rest of the board, and repaint it.

That way no board material goes to waste.

To cut PCB material, I

simply use a hand saw with a fine-toothed metal-cutting blade. I place

a rag over the board while holding it, so that I don't damage the

paint. I left a small margin on all sides, so that I can later sand the

PCB to the precise final size, with good finish of the edges.

There

are some smear marks on the remaining raw board, which happened during

cleaning with alcohol. They are of no consequence, and won't impair the

quality of future PCBs made with that board.

Etching

Before

I etch a PCB, I warm up the bottle of etchant by placing it in hot

water for half an hour, in the kitchen sink. I let it warm up while I

cut out the board, and store the laser engraver. Then I renew the hot

water in the sink, and float a plastic tray in it. The PCB goes

in it, copper side up, and warm etchant is poured into the tray. The

hot water keeps the etchant warm, and the floating tray can very easily

and comfortably be rocked in all directions, to keep the

etchant in constant agitation. I do this rocking by hand, since I'm a

patient guy, but more impatient people might want to build a

contraption with a motor to agitate the etchant. Agitation is very

important! Without it, the etchant would undercut the narrow traces

well before finishing the removal of copper from the larger

clear

areas. This effect is due to local exhaustion of the etchant in those

places where copper is more abundant.

Before

I etch a PCB, I warm up the bottle of etchant by placing it in hot

water for half an hour, in the kitchen sink. I let it warm up while I

cut out the board, and store the laser engraver. Then I renew the hot

water in the sink, and float a plastic tray in it. The PCB goes

in it, copper side up, and warm etchant is poured into the tray. The

hot water keeps the etchant warm, and the floating tray can very easily

and comfortably be rocked in all directions, to keep the

etchant in constant agitation. I do this rocking by hand, since I'm a

patient guy, but more impatient people might want to build a

contraption with a motor to agitate the etchant. Agitation is very

important! Without it, the etchant would undercut the narrow traces

well before finishing the removal of copper from the larger

clear

areas. This effect is due to local exhaustion of the etchant in those

places where copper is more abundant.

To etch double-sided

boards, I first wrap the board in a few loops of plastic-insulated

wire. So the board is inside a kind of cage, that protects both

surfaces from contact with the bottom of the tray. The wire touches the

board only at the edges, at the end of the wire is a convenient place

to grab with bare fingers and lift the board out of the juice to look

at its underside.

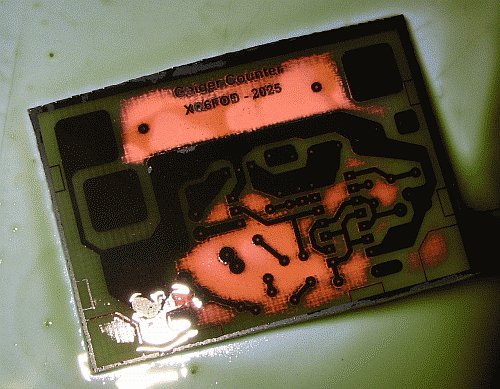

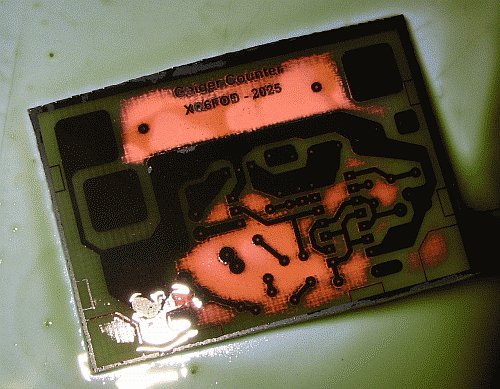

This

photo shows the board near the end of the etching process. Even with

vigorous agitation, the edges of the PCB complete first, and any large

clear areas away from the edges are the last to complete. The stronger

the agitation is, the less pronounced this unevenness is.

This

photo shows the board near the end of the etching process. Even with

vigorous agitation, the edges of the PCB complete first, and any large

clear areas away from the edges are the last to complete. The stronger

the agitation is, the less pronounced this unevenness is.

The total time required for etching a 35µm copper board is

about 10 minutes.

There are a lot of different copper etching solutions. Since acrylic

paint is pretty good at resisting chemicals, any of those etchants should work

fine with this method. Over the years I have used five or six different

etchants, but at the end I came back to the eternally renewable

chloride mix. This juice starts life as a simple

solution of ferric

chloride (AKA iron perchloride) in water, with about 300 grams per liter

being a decent strength. It can be used without further ado, but will

eventually become exhausted. It's here where maintenance of the

solution enters the scene.

When

iron perchloride (FeCl3) dissolves in water, some of the chloride ions

will split up some of the water (H2O), forming some hydrochloric acid

(HCl dissolved in water). This frees up some iron ions, which combine

with the hydroxide ions of the hydrolyzed water, to form iron

hydroxide, Fe(OH)3. This stuff, commonly known as rust, is

poorly

soluble, and will slowly settle in the bottom of the bottle, as a

rust-colored slurry. It's perfectly useless there. It looks as if not

all of the iron perchloride dissolved, but that's not the case. Some

people think that it's copper dust taken off the boards, but that's

also not the case. And what's worse is that when some water

evaporates out of the solution, more rust forms immediately, in very

fine specks, and settles in the pores of any surfaces it finds. So the

solution stains everything it touches, and has earned a bad reputation

for this.

But that doesn't need to be that way! To make good use

of the rust slurry in the bottom of the bottle, all that's needed is

adding some hydrochloric acid! The excess of chloride

ions will

reconvert the rust into iron perchloride. As long as the solution

contains enough hydrochloric acid, no new rust will form, and the

solution will no longer stain anything. It can actually be used to

remove stains it made before adding acid!

As the juice is

used to etch PCBs, iron perchloride (FeCl3) converts to iron-II chloride

(FeCl2), while the free chloride ions convert copper from the PCBs into

copper-I chloride (CuCl). Given an excess of chloride, coming from

hydrochloric acid, and free access to oxygen from the air, the copper-I

chloride will turn into copper perchloride (CuCl2), which is an

excellent etchant by itself!

The bottom line is that this

solution can be stored and used forever, just by letting it breathe

air, and adding some hydrochloric acid whenever it begins to form a

rust slurry in the bottom of the bottle. Over time the copper

perchloride contents will build up, gradually turning your

brown iron perchloride etchant into a green/blue, mostly copper perchloride etchant, but it

will

keep working.

Hydrochloric acid bought in a hardware store,

often called muriatic acid there, has a rather low

concentration,

so that by using this stuff you are adding far more water than

actual hydrochloric acid to your juice. But anyway a lot of water evaporates while

using the warm juice in an open tray, so that roughly

compensates.

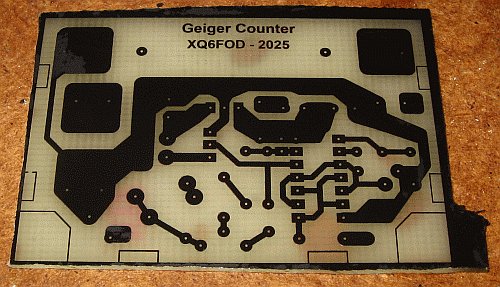

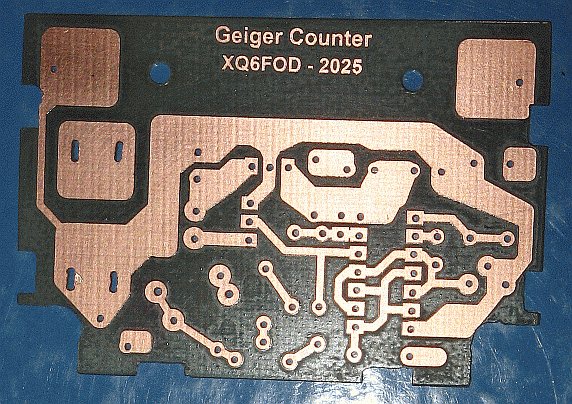

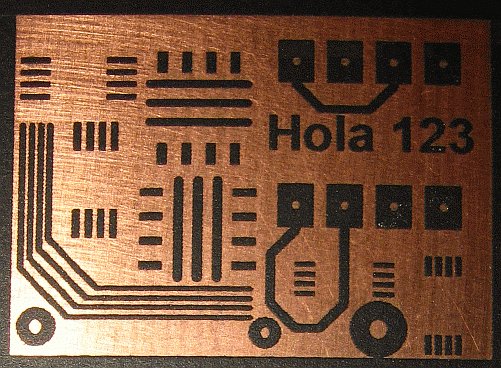

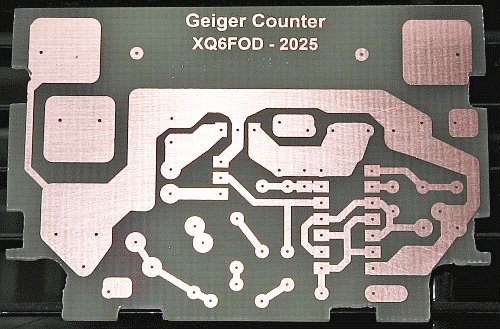

This

is the fully etched board, after rinsing and drying. There is a small

defect in one of the cutout markings, which I made with 0.2mm wide

traces. Probably I was a bit careless and scratched the paint there. It

doesn't matter. Also some very tiny specks of copper are left in the

area below the text. I didn't see them while etching. Just one more

minute in the etchant would have etched them away, but since they

don't affect the usability of the PCB, I didn't throw it back into the

etchant.

This

is the fully etched board, after rinsing and drying. There is a small

defect in one of the cutout markings, which I made with 0.2mm wide

traces. Probably I was a bit careless and scratched the paint there. It

doesn't matter. Also some very tiny specks of copper are left in the

area below the text. I didn't see them while etching. Just one more

minute in the etchant would have etched them away, but since they

don't affect the usability of the PCB, I didn't throw it back into the

etchant.

Borders

To

get the board to the exact size, my method is this: I design the board

in CiDess, defining the work area as the size of the PCB, with

zero margins, and I design

the board so that the borders of it are copper-free. That way at the

end of the etching process I get the board in the photo above, with the

PCB edge clearly marked by the transition from copper to no-copper. To

get

the board to the exact dimensions, I simply have to sand away all the

margins that still have copper. This is quick when using a belt

sander. It can also be done by placing a sheet of sandpaper on the

bench, business side up, and rubbing the board on it. It's quite a bit

slower

but also works well.

To

get the board to the exact size, my method is this: I design the board

in CiDess, defining the work area as the size of the PCB, with

zero margins, and I design

the board so that the borders of it are copper-free. That way at the

end of the etching process I get the board in the photo above, with the

PCB edge clearly marked by the transition from copper to no-copper. To

get

the board to the exact dimensions, I simply have to sand away all the

margins that still have copper. This is quick when using a belt

sander. It can also be done by placing a sheet of sandpaper on the

bench, business side up, and rubbing the board on it. It's quite a bit

slower

but also works well.

The Geiger counter board needed some cutouts, to

fit my project box. I marked those cutouts with 10 mil traces in the

design, but then I was lazy and made those cutouts with a handheld

Dremel tool, using a cutting disk and then a grinding stone. Since I'm

now an old guy, using half a dozen different glasses and still not seeing

well close-up, my cutouts came out horrible! But it doesn't

affect usability, so I called it a success anyway. The board does fit

the box, after all...

Paint removal, and surface protection

Since

I don't like to solder through stubborn stinky black paint, I prefer removing

the paint after etching the board. Sources say that acrylic paint

dissolves readily in acetone, but my acetone bottle was empty... and I

live a long drive away from the closest town, so sprinting out to buy

some acetone was not a good option. I looked around what I had. Alcohol

doesn't attack this paint. I tried lacquer thinner, with no results. I

also tried acrylic thinner, which is almost the same stuff, and it

didn't work either. That's strange, because both are supposed to contain quite

a lot of acetone, in addition to various other solvents!

Since

I don't like to solder through stubborn stinky black paint, I prefer removing

the paint after etching the board. Sources say that acrylic paint

dissolves readily in acetone, but my acetone bottle was empty... and I

live a long drive away from the closest town, so sprinting out to buy

some acetone was not a good option. I looked around what I had. Alcohol

doesn't attack this paint. I tried lacquer thinner, with no results. I

also tried acrylic thinner, which is almost the same stuff, and it

didn't work either. That's strange, because both are supposed to contain quite

a lot of acetone, in addition to various other solvents!

Scraping

the paint away is not something I would like to do. It would totally

scratch the copper, and maybe damage some trace.

So I

searched in my memories, and came up with one that tells that when

handling brake fluid one has to be careful to not let it drip on any

painted surface, because it attacks every paint known to mankind.

Bingo! I pilfered a few drops of DOT3 brake fluid out of my car,

spread it on the PCB, waited a while, and then simply wiped the brake

fluid and the paint off!

Leaving the copper unprotected will

cause it to tarnish over time. If the board won't be used in a harsh

environment, this isn't a problem, but PCBs look nicer if they stay

shiny even after many years. For that to happen, the copper needs to be

protected from the ambient. There are several ways to do it. Some

people love to apply a solder resist mask, but that involves as many

steps as making the PCB proper, so I think it's total overkill. Solder

masks make a lot of sense when an automatic soldering process is used,

that relies on the solder mask to make the solder go only where it has to.

But it makes almost no sense at all for hand soldering, which is what

homebrewers normally do! In fact a solder mask is a nuisance when it

comes to making modifications.

Other people use immersion tin

plating. That's indeed an excellent thing to do, being quick, providing

acceptable protection, long-time solderability, and looking good. The problem

is that a suitable tin plating solution is needed, and I haven't been

able to get any. Due to postal regulations... you know. Absolutely no

chemicals can be shipped. And to make my own, I need thiourea,

among other substances. I can get or make everything else required, but

not thiourea. So, no immersion tin plating for me.

Some

people painstakingly tin their boards with solder and a soldering iron,

or cover it with paste solder and then heat it up. That makes a thick,

good protective layer, but doesn't look very good.

So I resort

to varnishes. In the good old times, I sprayed Kontakt Chemie SK-10

solderable varnish on my boards, and that worked fine. Currently I use

a flux spray, made by an Argentinian company, but it stays somewhat

sticky, so it's not very nice. In between I have used shellac, very diluted

in alcohol, and brushed on. It works fine, but stinks while soldering.

A

good protection method for boards that will be used in harsh environments is to

leave the copper naked at first, assemble the circuit, test it, then

clean the board with alcohol, and spray polyurethane varnish over

everything, copper and solder joints. A board protected in that way can

be used in a harsh environment aboard a yacht for many years, and

remain perfectly good and shiny! But soldering through the polyurethane varnish,

in case repairs are needed, is dirty and stinky.

For my Geiger counter board I used the Argentinian flux lacquer spray.

Drilling

Some

people shudder when even just thinking about manually drilling a few

hundred little holes at precise locations on a large PCB. And indeed it

is somewhat of a nightmare, when the drill bit dances all around the

area and then makes a hole right between

two pads, or when the drill bit breaks, the spare one also breaks, and

then the spare of the spare breaks too, and you are left without drill

bits.

But

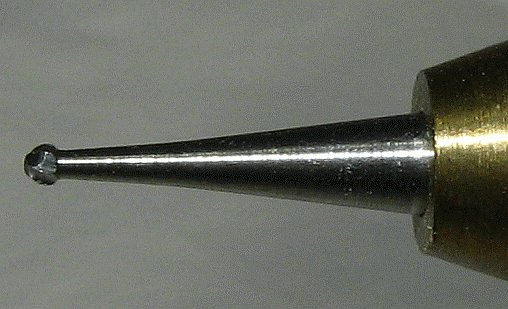

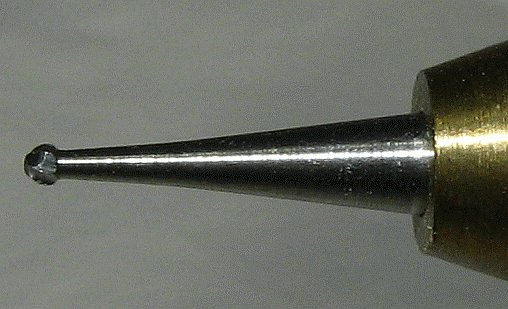

drilling PCBs is easy and quick, when using the correct tools, and

doing it the right way. The first point is using PCB software that

makes guide holes of the right size in each pad. These

little holes etched into the copper will guide the drill bit, so

that

every hole ends up quite precisely where it should, requiring little

effort. And the best drill bit to be used for the small holes in PCBs

is actually not a drill bit, but a dental bur! While drill bits

are long and of constant

diameter, making them break very easily, dental burs

are short

and have a conical shaft. I have never managed to break one!

But

drilling PCBs is easy and quick, when using the correct tools, and

doing it the right way. The first point is using PCB software that

makes guide holes of the right size in each pad. These

little holes etched into the copper will guide the drill bit, so

that

every hole ends up quite precisely where it should, requiring little

effort. And the best drill bit to be used for the small holes in PCBs

is actually not a drill bit, but a dental bur! While drill bits

are long and of constant

diameter, making them break very easily, dental burs

are short

and have a conical shaft. I have never managed to break one!

Dental

burs can be mounted in various sorts of motors and chucks. Inexpensive

handheld drill motors are available, but I used the motor of an old

8-track tape player, and made a very basic coupling piece on my lathe.