Voltage regulator for synchronous

generator

Most present-day synchronous generators come with a built-in voltage

regulator, fancily called automatic

voltage regulator,

or AVR. But that wasn't true many years ago. Very old machines from the

day before cheap electronics typically had an excitation scheme that

used a rheostat-adjusted voltage excitation, in addition to a

load-dependent component derived from a current transformer that sensed the load current. The user

had to crank the rheostat up and down as needed.

Years ago I built a small secondary microhydro system, using a plastic turbine,

and I got an old generator for free from a friend, to couple to my

turbine. This old generator came from an Honda E1000E gasoline-powered

genset, apparently made around 1970, whose engine had worn out beyond

reasonable repair. I got the bare generator, without any of the

external circuitry. So I had to make an AVR for it.

This generator has a main winding for 220 V, 1000 W, without any taps,

in addition to a tapped low voltage winding good for charging 6 V or

12 V batteries at several amperes, and it also has a 2×55 V

center-tapped winding, intended to provide excitation power. The field

winding, connected through slip rings and carbon brushes, has a

resistance of 15 Ω, and an inductance of very nearly 10 H.

The combination of a low resistance field winding with that relatively

high voltage excitation winding proved to be a problem. My first AVR for this

generator rectified and filtered the 55 V, obtaining roughly 70 VDC,

and applied this to the field winding through a typical AVR circuit,

using a bipolar Darlington power transistor in a self-oscillating zener-regulated

circuit. It sort of worked, but had a stupid problem: When the

generator was spinning too slow to achieve nominal output, the

regulator would apply full drive to the field coil, which at 70 V is

327 W, and that's rather hefty for a 1000 W generator! And it's totally

useless, because at about 20 V applied to the field, the generator's

iron totally saturates, and any further excitation doesn't increase the

output! But the 327 W excitation, plus losses in the totally

oversaturated iron, put such a hefty load on the turbine, that when the water supply was scarce it

failed to get up to the nominal running speed.

I tried powering the AVR from the 12 V winding instead, but that proved

to be too little. It maintained regulation only up to about 500 W load, and

beyond that the voltage would sag.

I tried adding the 12 VAC to 5 VAC obtained from an external

transformer, but it added only 1 V! This is because this generator,

like many, has the auxiliary windings installed 90 degrees out of phase

to the main winding, and so my 5 V transformer, powered from the

220 V output, was at 90 degrees with the 12 V winding.

The solution was to use the 12 V winding in combination with a voltage

doubler. That provides enough excitation even for full load, and at the

same time limits the excitation at undervoltage conditions to a

reasonable value, about 60 W. The cost is larger filter capacitors.

But I wonder why Honda put a 55 V excitation winding on that machine,

combined with such a low voltage field winding!

Another problem was lack of self-starting. Modern generators almost

always are made from materials that hold enough remanent magnetism to

allow the generator to self-excite when starting up.

Some

even include a small permanent magnet to assure quick self-starting. But not

this one!!! It has no magnet, and almost no remanence. When spinning it

up to full speed, the main winding generates less than one volt on

remanence, and the auxiliary winding can't overcome a diode drop!

Honda solved that problem nicely by providing external excitation to

the generator, taken from the engine's magneto. But my hydro turbine

doesn't have a magneto... So I had to add a small rechargeable battery

to my AVR, to provide start-up excitation! That works fine, but it

looks a bit odd to have batteries inside a generator!

And the third problem was an encounter with a counterfeit transistor. I

used a TIP142 in my first-generation AVR, and it died a very early

death. That was very

strange, because that transistor is enormous compared to the current,

voltage and power it had to master in this circuit! There is no chance

for the operation point to come anywhere close to the safe operation

area limits for that transistor.

Since I had bought several of those, very cheaply, in a local

electronic parts store, I took another, mounted it on a hefty heat

sink, and applied some controlled voltage and current to it. When I

made it conduct just slightly over 2 A, in saturation, with less than

3W dissipation, it shorted out! Definitely this was not

a

genuine TIP142. I don't know who faked them, and what type

they really are, but

certainly they are not usable in place of a real TIP142! The values of

the internal resistors also measured totally different from what the

TIP142 datasheet says.

Let this be a warning to my dear readers. Get your parts from reliable,

trustworthy distributors, not from any unknown eBay vendor,

and

not even from a small local parts store. The world has been swamped

with counterfeit parts, that simply don't perform anywhere close to the

datasheet specs. I have essentially stopped buying parts in local stores, for this reason.

Not having any other bipolar Darlington power transistor at hand, I

used a MOSFET instead, of which I had many. And that's how the final

AVR circuit for this Honda generator came to be.

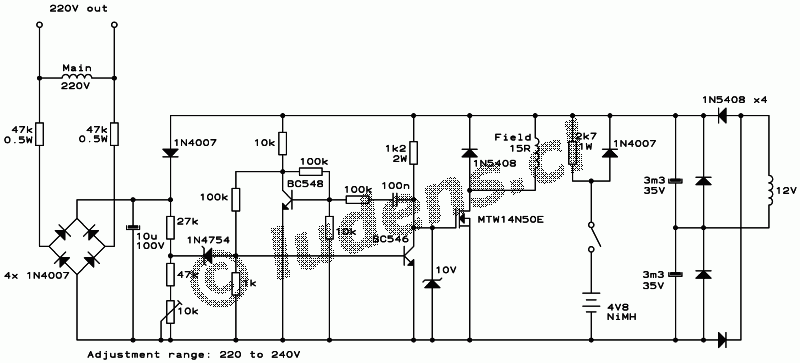

And now, finally,

you get to see

the schematic! And if you want to see it larger, or print it, just

click on it to get the big version.

If you have seen other AVR schematics, you will notice that this one is

quite similar in its fundamental operation. But there are some

differences to the most typical designs. For example, I placed the

10µF capacitor, which filters the voltage sample, behind a large portion

of the total resistance in the divider, unlike most designs that place

it pretty much at the input, without the 47k resistors in front of the

bridge rectifier. My approach is neither better nor worse than the

standard one. It's simply different. The standard design will tend to

regulate the peak voltage, while mine will tend to regulate the average

voltage. The former is best for powering electronic equipment, while the latter is best for avoiding light flickering.

The 12 V winding feeds a voltage doubler, that's made with 4 diodes,

rather than the more usual 2-diode design. The additional diodes

basically provide protection against reverse polarity on the filter

caps, in the event of any weird phenomenom occuring in the generator's

stator, caused by loads with poor power factors. Most likely these

extra diodes aren't really required, but they are cheap protection. And if

you want me to be honest to the bones, I have to confess that mainly I

have them in the circuit because I was too lazy to remove them, when I

changed the rectifier configuration from a bridge to a voltage doubler!

The 1N4007 feeding supply voltage into the 10µF capacitor is another

useless remnant. In my original AVR, powered by the 55V winding, this

diode would become forward biased when the generator is

loaded by

a very crooked load (low power factor), that drives up the 55V and down

the 220V. This diode would then make the AVR regulate the

55 V

winding rather than the depressed main one, providing protection against burning

out the AVR from excessive supply voltage. Now, with the

AVR powered from about 25V, there is no risk of this, and at the same

time this diode will never be forward biased, and is thus exemplarily

useless! I didn't remove it because of sheer laziness (did I mention

already that I have been becoming lazy lately?), but you might want to

use this idea if you will adapt this AVR to some generator that does

need a higher excitation supply voltage than mine.

The most special part in this AVR is the battery pack, which consists

of four AA-size NiMH cells. It's provided with a switch, so the

battery can be disconnected when the generator is not in use. When the

switch is on, the battery powers the circuit through the diode,

providing enough voltage to turn the MOSFET on, and puts enough current

through the field winding to make the generator start up at once, when

it begins rotating. During normal operation, the battery is

trickle-charged through the 2k7 resistor. If you are making an AVR for

a generator that has enough remanence to self-excite, then of course

you don't need to include the battery circuit! But with such a

generator you might want either a bipolar transistor, or a MOSFET or

IGBT with a very low threshold voltage, instead of the standard MOSFET

I used. Because that generator might generate enough voltage on

remanence to overcome the rectifier diodes' drop, but not enough to

bias a normal MOSFET into conduction!

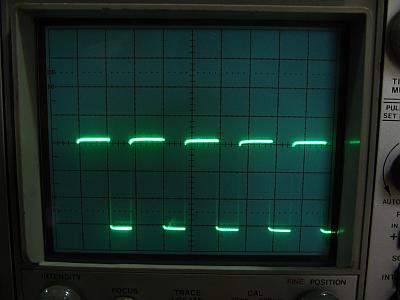

The

two small transistors and the power MOSFET constitute a pulse width

modulation cell, that modulates cleanly all the way from zero to 100% duty cycle.

The scope screenshot shows the waveform at the MOSFET. The

frequency is low, around 100 Hz, leading to high switching efficiency

despite the large gate resistor. A higher frequency isn't needed,

because of the very high inductance of the field winding, which holds

the field current highly constant while the field voltage switches

between zero and about 25V at 100Hz.

The

two small transistors and the power MOSFET constitute a pulse width

modulation cell, that modulates cleanly all the way from zero to 100% duty cycle.

The scope screenshot shows the waveform at the MOSFET. The

frequency is low, around 100 Hz, leading to high switching efficiency

despite the large gate resistor. A higher frequency isn't needed,

because of the very high inductance of the field winding, which holds

the field current highly constant while the field voltage switches

between zero and about 25V at 100Hz.

The control loop response is that of a simple proportional function

with a narrow action range (high gain). It holds the

voltage

"stable as a plank" during speed and load variations, at least when

looking at it on my analog panel voltmeter! Actually the output voltage

fluctuates by about 1% when the load changes from zero tu full, but

that's pretty acceptable. The good thing is that such a simple, slow,

proportional controller is unconditionally stable.

The component values were chosen so that with the trimpot at the center

of its range, the output voltage is regulated to 230 V, with the

components I got. The range of the trimpot should be enough to

compensate for the normal tolerance of the parts. The zener diode is

used at pretty low current, though, so it might happen that

you

get one that has a significantly different zener voltage than mine, at

that current. In that case feel free to change the value of the 47k

resistor in series with the pot, as needed to get the proper output voltage

while the pot is in a reasonable position.

The MOSFET I used is brutally oversized for the task. I used it because

I was given a large bag full of them. Feel free to use a different one.

There isn't much more to say, really. It's a simple circuit.

I built this AVR in the "printed-circuit-boards-are-for-sissies" style.

Anyway it would have been hard to make a board that fits

under the

back cover of this generator with the big parts on it - and instead my

antique-radio-reminiscent construction fits very well!

I bolted the MOSFET to a convenient hole in the generator's housing,

which is made from thick cast aluminium, and makes a marvelous

heatsink. Normally a heatsink isn't even necessary in this circuit, but

if the oscillation should stop for any reason, and the MOSFET goes into linear mode,

the heatsink will save its life.

Then I mounted the switch on a simple bracket, tied down the battery

pack and some other large parts with double-sided foam tape "for heavy

object mounting" and cable ties, bolted three terminal strips to

additional threaded holes in the casting (thanks, Honda, for all those

convenient holes!), and soldered the other parts and the wires to them.

Ready. It works perfectly, and after closing the cover it even starts to look

good!

With

a generator driven from a combustion engine, this construction

style might not be entirely optimal, as some long-legged parts might

enter resonance and end up fatiguing and breaking their legs. But I'm

running the generator from

a water turbine, which is basically vibration-free, so it has worked

fine for several years. Once a year I check the brushes, and clean the

carbon dust from the circuit, using a paintbrush and a vacuum cleaner.

With

a generator driven from a combustion engine, this construction

style might not be entirely optimal, as some long-legged parts might

enter resonance and end up fatiguing and breaking their legs. But I'm

running the generator from

a water turbine, which is basically vibration-free, so it has worked

fine for several years. Once a year I check the brushes, and clean the

carbon dust from the circuit, using a paintbrush and a vacuum cleaner.

Okay. If you need an AVR, you might go into all the trouble to build

your own, adapting my circuit to the needs of your generator, or using

another standard design, or designing your own from scratch. I hope my

circuit gives you some useful ideas in that case. Or you can go to eBay

and buy a ready-made Chinese AVR for surprisingly little money. They

are available in many models, for many generators, and most of them do indeed work -

at least for some time. The problem with many of them is that they are

built to the absolute minimum expression, they have no heatsink, have

very tiny electrolytic caps, and so on. For a generator used a few

times per year during power outages or camping trips, they might be all

you need, but for a generator that will run 24/7 for many years, you

need something designed with a bit more headroom, specially to make the

electrolytic capacitors last. For such applications, a homemade AVR is a good idea.

It's also educational and fun to build your own.

Back to homo ludens electronicus.

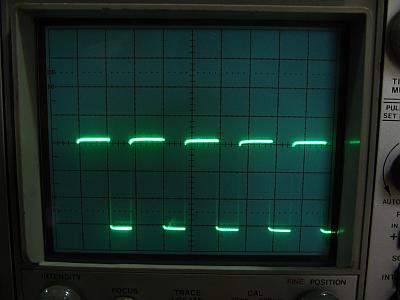

The

two small transistors and the power MOSFET constitute a pulse width

modulation cell, that modulates cleanly all the way from zero to 100% duty cycle.

The scope screenshot shows the waveform at the MOSFET. The

frequency is low, around 100 Hz, leading to high switching efficiency

despite the large gate resistor. A higher frequency isn't needed,

because of the very high inductance of the field winding, which holds

the field current highly constant while the field voltage switches

between zero and about 25V at 100Hz.

The

two small transistors and the power MOSFET constitute a pulse width

modulation cell, that modulates cleanly all the way from zero to 100% duty cycle.

The scope screenshot shows the waveform at the MOSFET. The

frequency is low, around 100 Hz, leading to high switching efficiency

despite the large gate resistor. A higher frequency isn't needed,

because of the very high inductance of the field winding, which holds

the field current highly constant while the field voltage switches

between zero and about 25V at 100Hz.

With

a generator driven from a combustion engine, this construction

style might not be entirely optimal, as some long-legged parts might

enter resonance and end up fatiguing and breaking their legs. But I'm

running the generator from

a water turbine, which is basically vibration-free, so it has worked

fine for several years. Once a year I check the brushes, and clean the

carbon dust from the circuit, using a paintbrush and a vacuum cleaner.

With

a generator driven from a combustion engine, this construction

style might not be entirely optimal, as some long-legged parts might

enter resonance and end up fatiguing and breaking their legs. But I'm

running the generator from

a water turbine, which is basically vibration-free, so it has worked

fine for several years. Once a year I check the brushes, and clean the

carbon dust from the circuit, using a paintbrush and a vacuum cleaner.